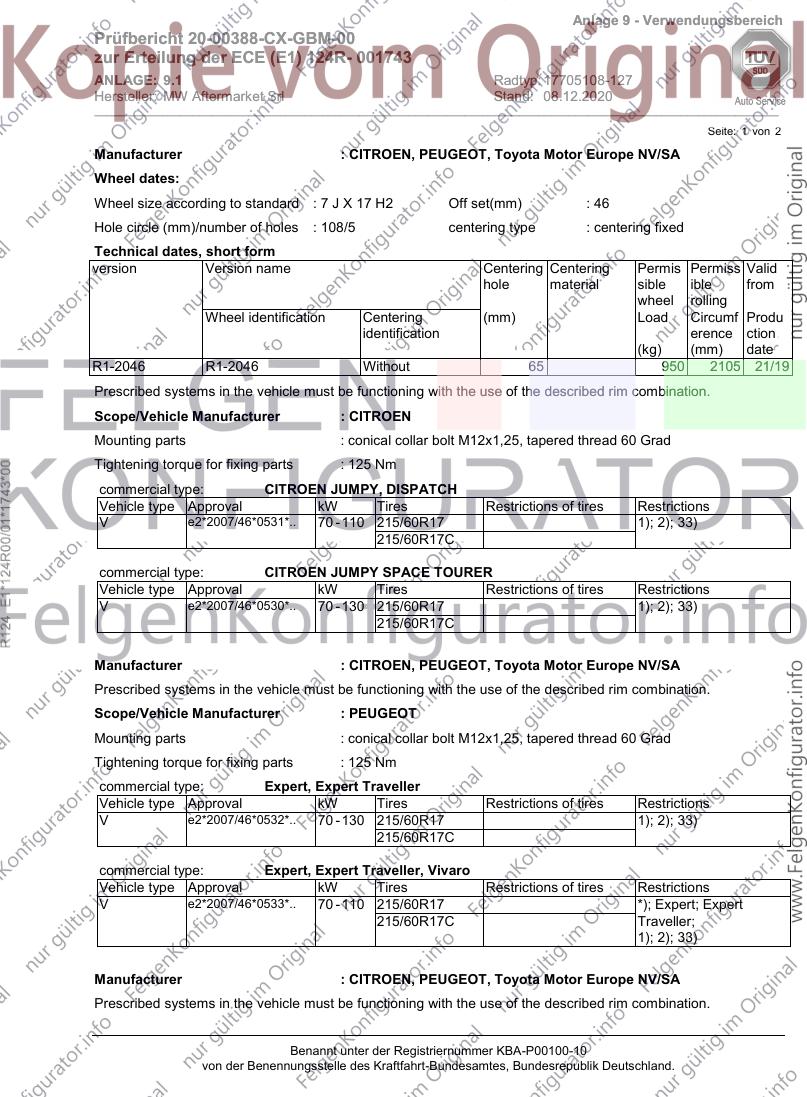

Anlage 9 - Verwendungsbereich

Prüfbericht 20-00388-CX-GBM-00

zur Erteilung der ECE (E1) 124R- 001743

ANLAGE: 9.1 Radtyp: 17705108-127

Hersteller: MW Aftermarket Srl Stand: 08.12.2020

_______________________________________________________________________________________________________________

Seite: 1 von 2

Manufacturer : CITROEN, PEUGEOT, Toyota Motor Europe NV/SA

Wheel dates:

Wheel size according to standard : 7 J X 17 H2 Off set(mm) : 46

Hole circle (mm)/number of holes : 108/5 centering type : centering fixed

Technical dates, short form

version Version name Centering Centering Permis Permiss Valid

hole material sible ible from

wheel rolling

Wheel identification Centering (mm) Load Circumf Produ

identification erence ction

(kg) (mm) date

R1-2046 R1-2046 Without 65 950 2105 21/19

Prescribed systems in the vehicle must be functioning with the use of the described rim combination.

Scope/Vehicle Manufacturer : CITROEN

Mounting parts : conical collar bolt M12x1,25, tapered thread 60 Grad

Tightening torque for fixing parts : 125 Nm

R124 E1*124R00/01*1743*00

commercial type: CITROEN JUMPY, DISPATCH

Vehicle type Approval kW Tires Restrictions of tires Restrictions

V e2*2007/46*0531*.. 70 - 110 215/60R17 1); 2); 33)

215/60R17C

commercial type: CITROEN JUMPY SPACE TOURER

Vehicle type Approval kW Tires Restrictions of tires Restrictions

V e2*2007/46*0530*.. 70 - 130 215/60R17 1); 2); 33)

215/60R17C

Manufacturer : CITROEN, PEUGEOT, Toyota Motor Europe NV/SA

Prescribed systems in the vehicle must be functioning with the use of the described rim combination.

Scope/Vehicle Manufacturer : PEUGEOT

Mounting parts : conical collar bolt M12x1,25, tapered thread 60 Grad

Tightening torque for fixing parts : 125 Nm

commercial type: Expert, Expert Traveller

Vehicle type Approval kW Tires Restrictions of tires Restrictions

V e2*2007/46*0532*.. 70 - 130 215/60R17 1); 2); 33)

215/60R17C

commercial type: Expert, Expert Traveller, Vivaro

Vehicle type Approval kW Tires Restrictions of tires Restrictions

V e2*2007/46*0533*.. 70 - 110 215/60R17 *); Expert; Expert

215/60R17C Traveller;

1); 2); 33)

Manufacturer : CITROEN, PEUGEOT, Toyota Motor Europe NV/SA

Prescribed systems in the vehicle must be functioning with the use of the described rim combination.

Benannt unter der Registriernummer KBA-P00100-10

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

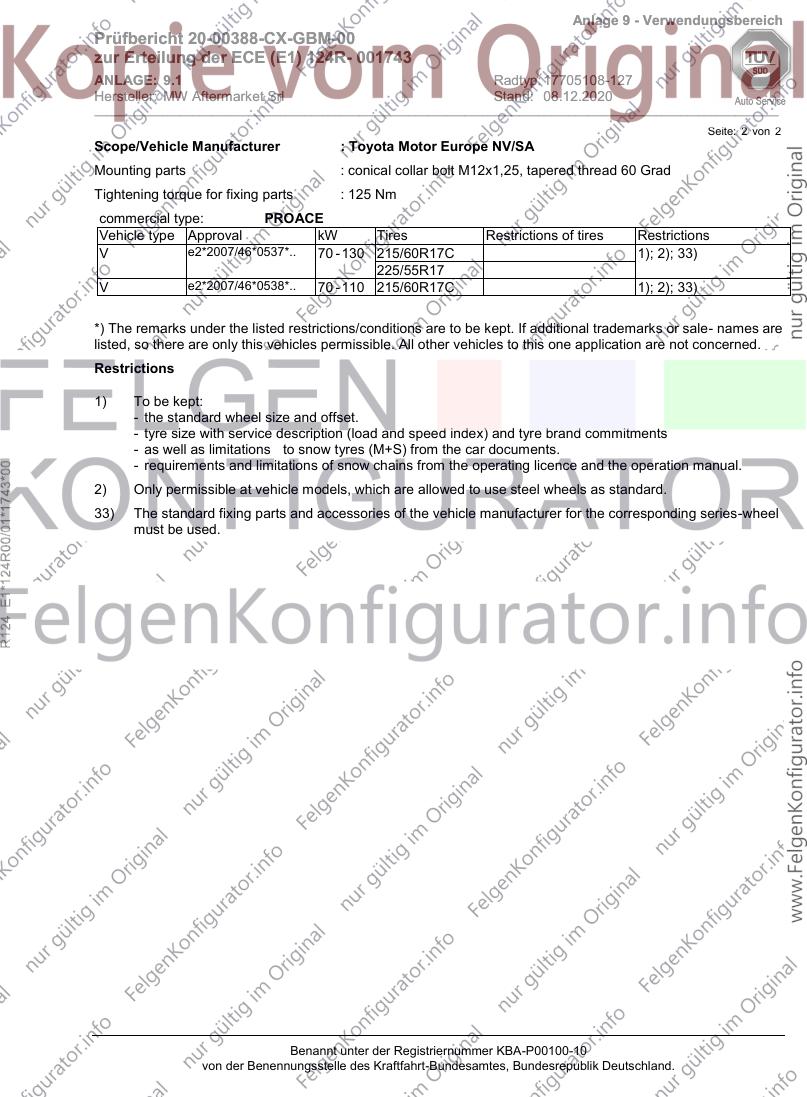

� Anlage 9 - Verwendungsbereich

Prüfbericht 20-00388-CX-GBM-00

zur Erteilung der ECE (E1) 124R- 001743

ANLAGE: 9.1 Radtyp: 17705108-127

Hersteller: MW Aftermarket Srl Stand: 08.12.2020

_______________________________________________________________________________________________________________

Seite: 2 von 2

Scope/Vehicle Manufacturer : Toyota Motor Europe NV/SA

Mounting parts : conical collar bolt M12x1,25, tapered thread 60 Grad

Tightening torque for fixing parts : 125 Nm

commercial type: PROACE

Vehicle type Approval kW Tires Restrictions of tires Restrictions

V e2*2007/46*0537*.. 70 - 130 215/60R17C 1); 2); 33)

225/55R17

V e2*2007/46*0538*.. 70 - 110 215/60R17C 1); 2); 33)

*) The remarks under the listed restrictions/conditions are to be kept. If additional trademarks or sale- names are

listed, so there are only this vehicles permissible. All other vehicles to this one application are not concerned.

Restrictions

1) To be kept:

- the standard wheel size and offset.

- tyre size with service description (load and speed index) and tyre brand commitments

- as well as limitations to snow tyres (M+S) from the car documents.

- requirements and limitations of snow chains from the operating licence and the operation manual.

R124 E1*124R00/01*1743*00

2) Only permissible at vehicle models, which are allowed to use steel wheels as standard.

33) The standard fixing parts and accessories of the vehicle manufacturer for the corresponding series-wheel

must be used.

Benannt unter der Registriernummer KBA-P00100-10

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

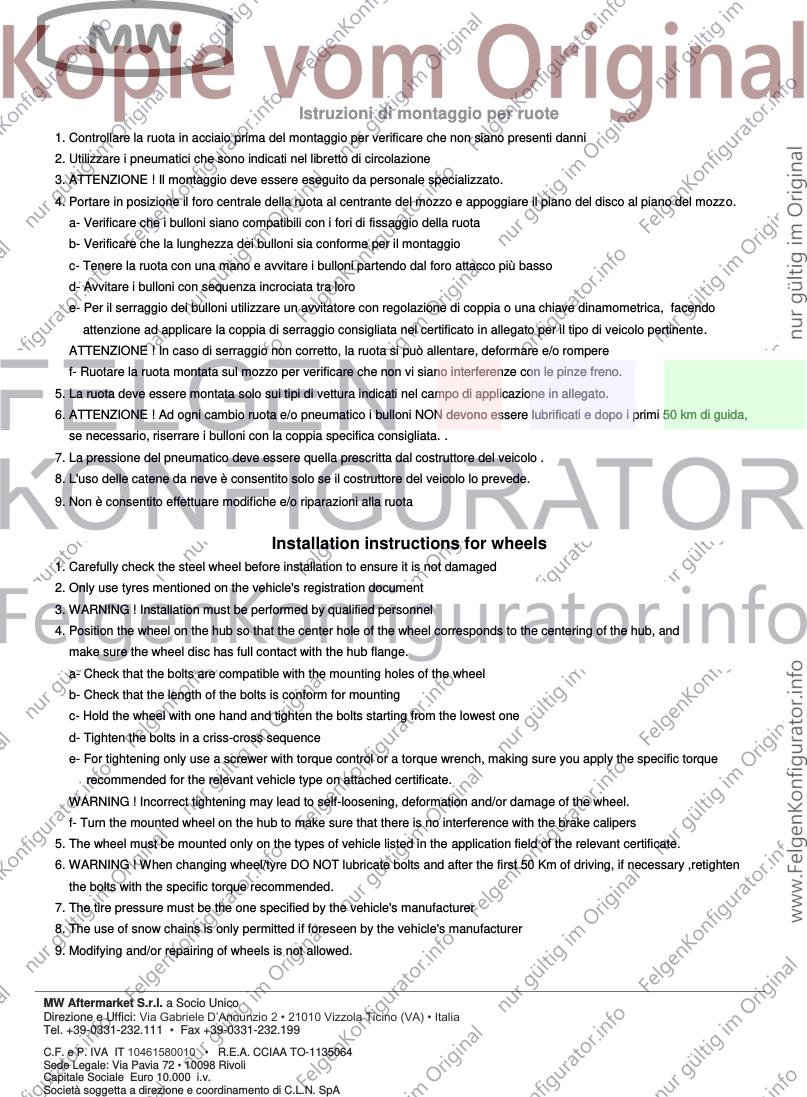

� Istruzioni di montaggio per ruote

1. Controllare la ruota in acciaio prima del montaggio per verificare che non siano presenti danni

2. Utilizzare i pneumatici che sono indicati nel libretto di circolazione

3. ATTENZIONE ! Il montaggio deve essere eseguito da personale specializzato.

4. Portare in posizione il foro centrale della ruota al centrante del mozzo e appoggiare il piano del disco al piano del mozzo.

a- Verificare che i bulloni siano compatibili con i fori di fissaggio della ruota

b- Verificare che la lunghezza dei bulloni sia conforme per il montaggio

c- Tenere la ruota con una mano e avvitare i bulloni partendo dal foro attacco più basso

d- Avvitare i bulloni con sequenza incrociata tra loro

e- Per il serraggio dei bulloni utilizzare un avvitatore con regolazione di coppia o una chiave dinamometrica, facendo

attenzione ad applicare la coppia di serraggio consigliata nel certificato in allegato per il tipo di veicolo pertinente.

ATTENZIONE ! In caso di serraggio non corretto, la ruota si può allentare, deformare e/o rompere

f- Ruotare la ruota montata sul mozzo per verificare che non vi siano interferenze con le pinze freno.

5. La ruota deve essere montata solo sui tipi di vettura indicati nel campo di applicazione in allegato.

6. ATTENZIONE ! Ad ogni cambio ruota e/o pneumatico i bulloni NON devono essere lubrificati e dopo i primi 50 km di guida,

se necessario, riserrare i bulloni con la coppia specifica consigliata. .

7. La pressione del pneumatico deve essere quella prescritta dal costruttore del veicolo .

8. L'uso delle catene da neve è consentito solo se il costruttore del veicolo lo prevede.

9. Non è consentito effettuare modifiche e/o riparazioni alla ruota

Installation instructions for wheels

1. Carefully check the steel wheel before installation to ensure it is not damaged

2. Only use tyres mentioned on the vehicle's registration document

3. WARNING ! Installation must be performed by qualified personnel

4. Position the wheel on the hub so that the center hole of the wheel corresponds to the centering of the hub, and

make sure the wheel disc has full contact with the hub flange.

a- Check that the bolts are compatible with the mounting holes of the wheel

b- Check that the length of the bolts is conform for mounting

c- Hold the wheel with one hand and tighten the bolts starting from the lowest one

d- Tighten the bolts in a criss-cross sequence

e- For tightening only use a screwer with torque control or a torque wrench, making sure you apply the specific torque

recommended for the relevant vehicle type on attached certificate.

WARNING ! Incorrect tightening may lead to self-loosening, deformation and/or damage of the wheel.

f- Turn the mounted wheel on the hub to make sure that there is no interference with the brake calipers

5. The wheel must be mounted only on the types of vehicle listed in the application field of the relevant certificate.

6. WARNING ! When changing wheel/tyre DO NOT lubricate bolts and after the first 50 Km of driving, if necessary ,retighten

the bolts with the specific torque recommended.

7. The tire pressure must be the one specified by the vehicle's manufacturer

8. The use of snow chains is only permitted if foreseen by the vehicle's manufacturer

9. Modifying and/or repairing of wheels is not allowed.

MW Aftermarket S.r.l. a Socio Unico

Direzione e Uffici: Via Gabriele D’Annunzio 2 • 21010 Vizzola Ticino (VA) • Italia

Tel. +39-0331-232.111 • Fax +39-0331-232.199

C.F. e P. IVA IT 10461580010 • R.E.A. CCIAA TO-1135064

Sede Legale: Via Pavia 72 • 10098 Rivoli

Capitale Sociale Euro 10.000 i.v.

Società soggetta a direzione e coordinamento di C.L.N. SpA

�