Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 1 von 8

Test Report

No. 366-0006-16-WIRD

According to the agreement concerning the adoption of uniform technical prescriptions for

wheeled vehicles, equipment and parts which can be fitted and/or be used on wheeled vehicles

and the conditions for reciprocal recognition of approvals granted on the basis of these

prescriptions.

Uniform provisions concerning the approval of wheels for

passenger cars and their trailers

ECE-R 124 last amended on 30.01.2011

Approval status

Number of approval Wheel part number

ECE (E1)-124 R - 001064 R1-1638

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 2 von 8

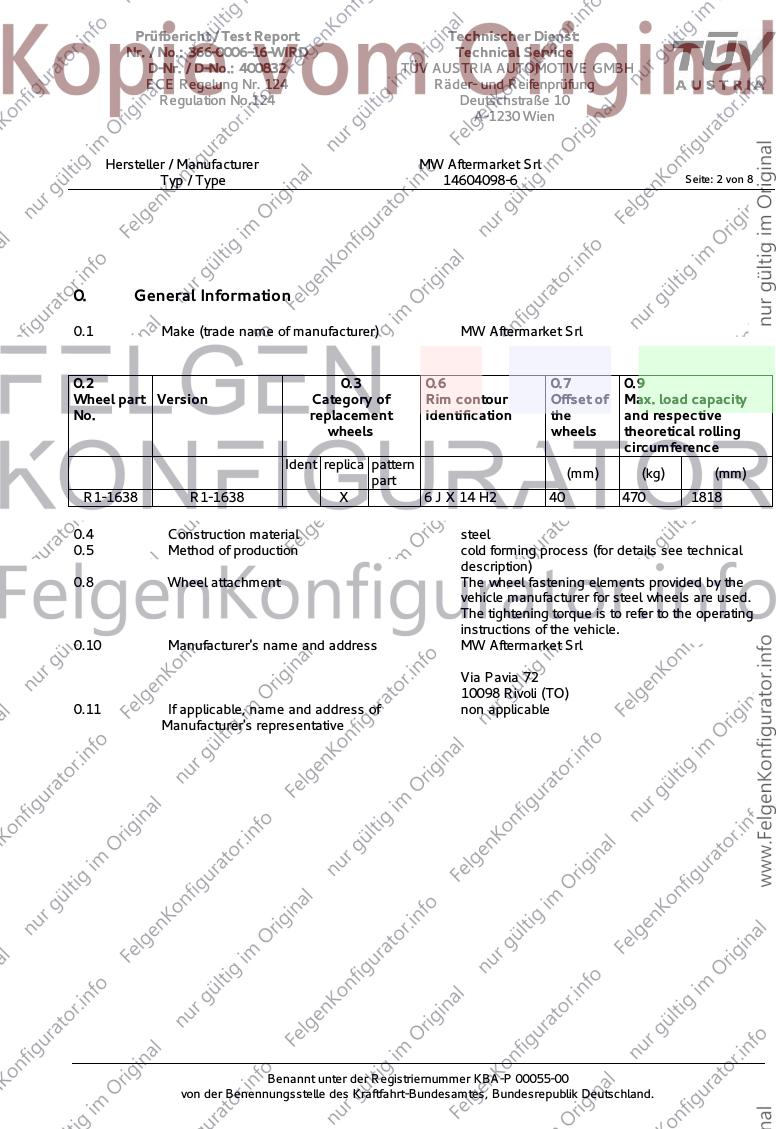

0. General Information

0.1 Make (trade name of manufacturer) MW Aftermarket Srl

0.2 0.3 0.6 0.7 0.9

Wheel part Version Category of Rim contour Offset of Max. load capacity

No. replacement identification the and respective

wheels wheels theoretical rolling

circumference

Ident replica pattern

(mm) (kg) (mm)

part

R1-1638 R1-1638 X 6 J X 14 H2 40 470 1818

0.4 Construction material steel

0.5 Method of production cold forming process (for details see technical

description)

0.8 Wheel attachment The wheel fastening elements provided by the

vehicle manufacturer for steel wheels are used.

The tightening torque is to refer to the operating

instructions of the vehicle.

0.10 Manufacturer's name and address MW Aftermarket Srl

Via Pavia 72

10098 Rivoli (TO)

0.11 If applicable, name and address of non applicable

Manufacturer's representative

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 3 von 8

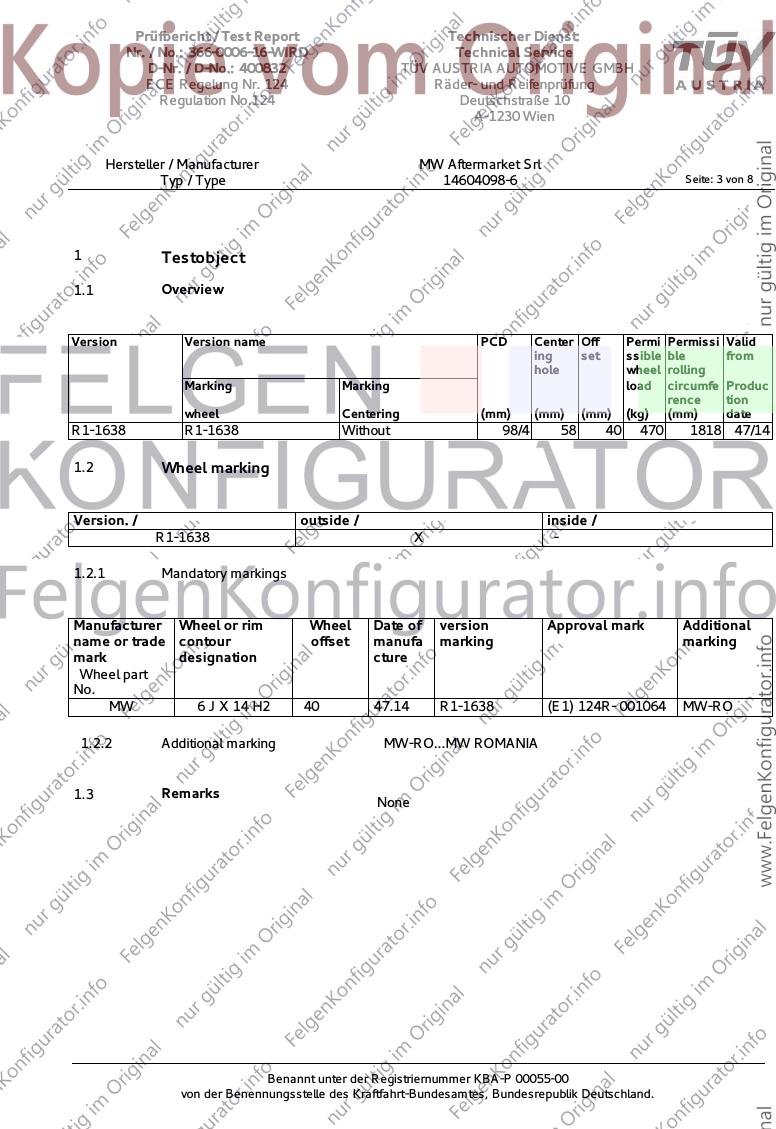

1 Testobject

1.1 Overview

Version Version name PCD Center Off Permi Permissi Valid

ing set ssible ble from

hole wheel rolling

Marking Marking load circumfe Produc

rence tion

wheel Centering (mm) (mm) (mm) (kg) (mm) date

R1-1638 R1-1638 Without 98/4 58 40 470 1818 47/14

1.2 Wheel marking

Version. / outside / inside /

R1-1638 X -

1.2.1 Mandatory markings

Manufacturer Wheel or rim Wheel Date of version Approval mark Additional

name or trade contour offset manufa marking marking

mark designation cture

Wheel part

No.

MW 6 J X 14 H2 40 47.14 R1-1638 (E1) 124R- 001064 MW-RO

1.2.2 Additional marking MW-RO...MW ROMANIA

1.3 Remarks

None

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 4 von 8

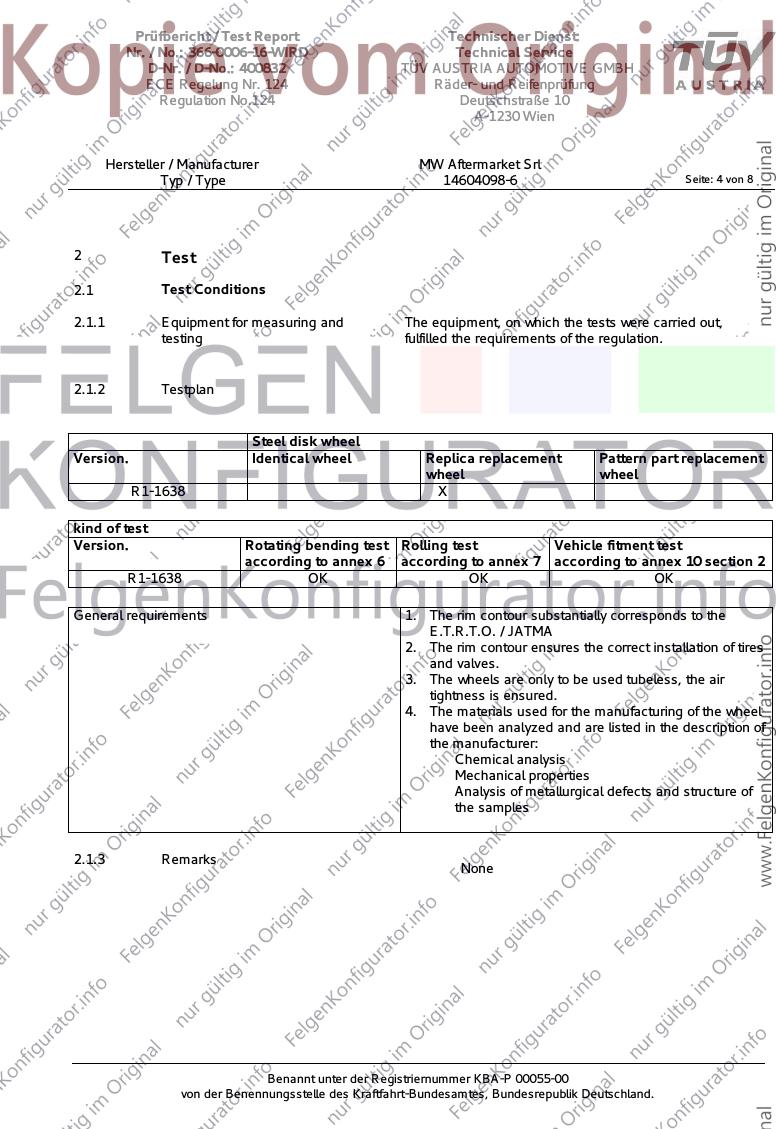

2 Test

2.1 Test Conditions

2.1.1 Equipment for measuring and The equipment, on which the tests were carried out,

testing fulfilled the requirements of the regulation.

2.1.2 Testplan

Steel disk wheel

Version. Identical wheel Replica replacement Pattern part replacement

wheel wheel

R1-1638 X

kind of test

Version. Rotating bending test Rolling test Vehicle fitment test

according to annex 6 according to annex 7 according to annex 10 section 2

R1-1638 OK OK OK

General requirements 1. The rim contour substantially corresponds to the

E.T.R.T.O. / JATMA

2. The rim contour ensures the correct installation of tires

and valves.

3. The wheels are only to be used tubeless, the air

tightness is ensured.

4. The materials used for the manufacturing of the wheel

have been analyzed and are listed in the description of

the manufacturer:

Chemical analysis

Mechanical properties

Analysis of metallurgical defects and structure of

the samples

2.1.3 Remarks

None

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 5 von 8

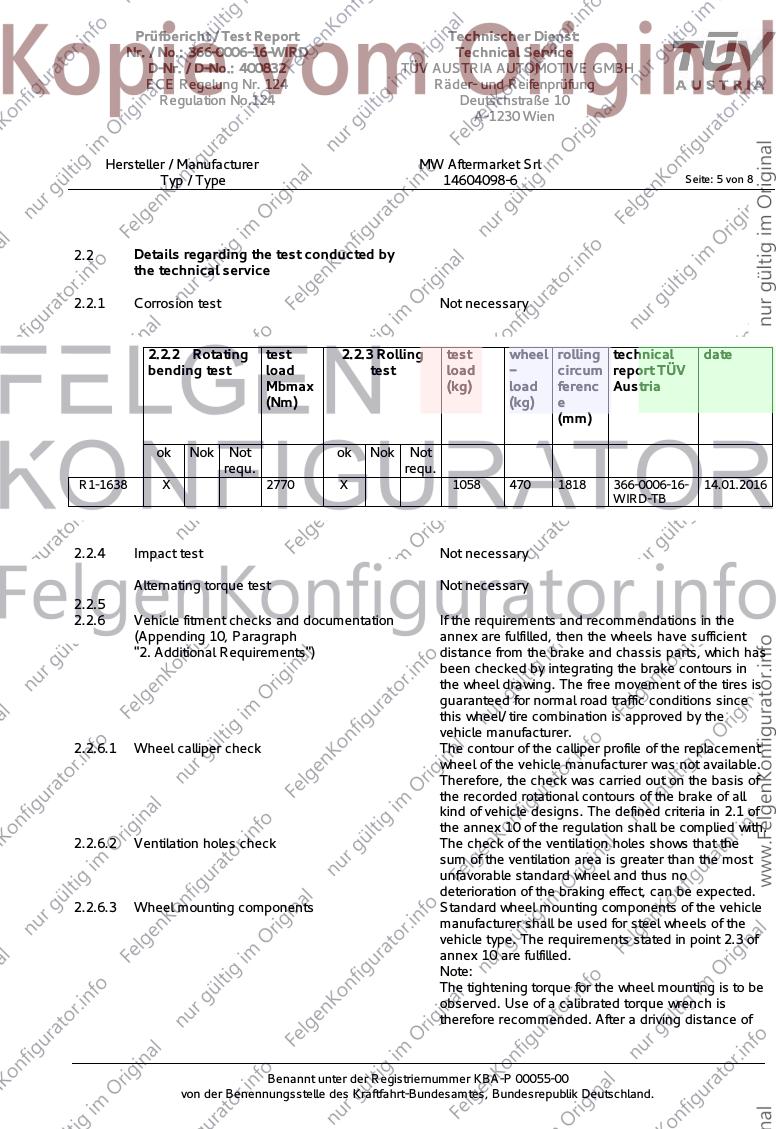

2.2 Details regarding the test conducted by

the technical service

2.2.1 Corrosion test Not necessary

2.2.2 Rotating test 2.2.3 Rolling test wheel rolling technical date

bending test load test load - circum report TÜV

Mbmax (kg) load ferenc Austria

(Nm) (kg) e

(mm)

ok Nok Not ok Nok Not

requ. requ.

R1-1638 X 2770 X 1058 470 1818 366-0006-16- 14.01.2016

WIRD-TB

2.2.4 Impact test Not necessary

Alternating torque test Not necessary

2.2.5

2.2.6 Vehicle fitment checks and documentation If the requirements and recommendations in the

(Appending 10, Paragraph annex are fulfilled, then the wheels have sufficient

"2. Additional Requirements") distance from the brake and chassis parts, which has

been checked by integrating the brake contours in

the wheel drawing. The free movement of the tires is

guaranteed for normal road traffic conditions since

this wheel/ tire combination is approved by the

vehicle manufacturer.

2.2.6.1 Wheel calliper check The contour of the calliper profile of the replacement

wheel of the vehicle manufacturer was not available.

Therefore, the check was carried out on the basis of

the recorded rotational contours of the brake of all

kind of vehicle designs. The defined criteria in 2.1 of

the annex 10 of the regulation shall be complied with.

2.2.6.2 Ventilation holes check The check of the ventilation holes shows that the

sum of the ventilation area is greater than the most

unfavorable standard wheel and thus no

deterioration of the braking effect, can be expected.

2.2.6.3 Wheel mounting components Standard wheel mounting components of the vehicle

manufacturer shall be used for steel wheels of the

vehicle type. The requirements stated in point 2.3 of

annex 10 are fulfilled.

Note:

The tightening torque for the wheel mounting is to be

observed. Use of a calibrated torque wrench is

therefore recommended. After a driving distance of

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 6 von 8

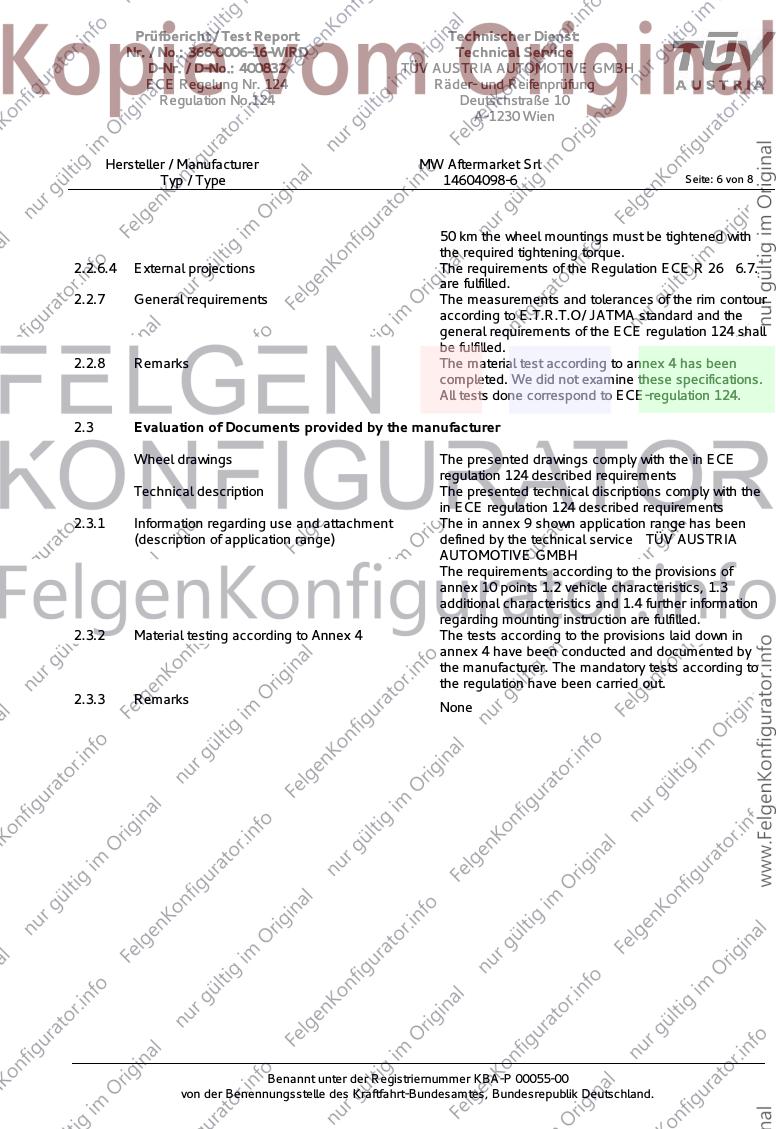

50 km the wheel mountings must be tightened with

the required tightening torque.

2.2.6.4 External projections The requirements of the Regulation ECE R 26 6.7.

are fulfilled.

2.2.7 General requirements The measurements and tolerances of the rim contour

according to E.T.R.T.O/ JATMA standard and the

general requirements of the ECE regulation 124 shall

be fulfilled.

2.2.8 Remarks The material test according to annex 4 has been

completed. We did not examine these specifications.

All tests done correspond to ECE-regulation 124.

2.3 Evaluation of Documents provided by the manufacturer

Wheel drawings The presented drawings comply with the in ECE

regulation 124 described requirements

Technical description The presented technical discriptions comply with the

in ECE regulation 124 described requirements

2.3.1 Information regarding use and attachment The in annex 9 shown application range has been

(description of application range) defined by the technical service TÜV AUSTRIA

AUTOMOTIVE GMBH

The requirements according to the provisions of

annex 10 points 1.2 vehicle characteristics, 1.3

additional characteristics and 1.4 further information

regarding mounting instruction are fulfilled.

2.3.2 Material testing according to Annex 4 The tests according to the provisions laid down in

annex 4 have been conducted and documented by

the manufacturer. The mandatory tests according to

the regulation have been carried out.

2.3.3 Remarks

None

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 7 von 8

2.4 General information

2.4.1 Place of testing TÜV AUSTRIA AUTOMOTIVE GMBH

Deutschstraße 10, A-1230 Wien

2.4.2 Date of testing The tests took place in the period of

26.10.2015-14.01.2016.

2.4.3 Remarks

For these wheels enclosed in this type already

an ABE approval is requested or available

(KBA44550*30).

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Prüfbericht / Test Report Technischer Dienst:

Nr. / No.: 366-0006-16-WIRD Technical Service

D-Nr. / D-No.: 400832 TÜV AUSTRIA AUTOMOTIVE GMBH

ECE Regelung Nr. 124 Räder- und Reifenprüfung

Regulation No.124 Deutschstraße 10

A-1230 Wien

Hersteller / Manufacturer MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 8 von 8

3 Technical documentation

see annex technical documentation

4 Statement of conformity

The type described in this test report and the appendices attached are in compliance with the Test

Specification mentioned above.

The tests were carried out in accordance with the relevant requirements of EN ISO/IEC 17025:2005

The Test Report comprises pages 1 to 8.

The reproduction and/or duplication of this document in extracts is subject to the written approval by

TÜV AUSTRIA AUTOMOTIVE GMBH.

Wien, 14.01.2016

TÜV AUSTRIA AUTOMOTIVE GMBH

Designated by the designation body of the

Kraftfahrt-Bundesamt (KBA), Germany

under the number

KBA-P 00055-00

Cinibulk

Expert

Test laboratory DIN EN ISO/IEC

17025

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Appendix 1 / Technical Service:

Nr. / No.: 366-0006-16-WIRD

D-Nr. / D-No.: 354166/3000 TÜV AUSTRIA AUTOMOTIVE GMBH

Regulation No.124 Räder- und Reifenprüfung

Deutschstraße 10

A-1230 Wien

Manufacturer / MW Aftermarket Srl

Typ / Type 14604098-6 Seite: 1 von 1

List of modifications

Details of application of Date 14.01.2016

Correction of

Modification of

Addition of

Deletion of

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Anlage 2 - Technische Unterlagen

Prüfbericht 366-0006-16-WIRD

zur Erteilung der ECE (E1) 124R- 001064

ANLAGE: Technische Unterlagen Radtyp: 14604098-6

Hersteller: MW Aftermarket Srl Stand: 14.01.2016

__________________________________________________________________________________________________________________

Seite: 1 von 1

The following documentation referring to the approval:

Description Documentation Date / extension / Date

1 - List of modifications Annex 1 - new 14.01.2016

2 - Techn.documentation this annex 14.01.2016

3 - Summary TBS 14604098-6-0 14.01.2016

4 - General description TGD-ECE GA_04-00 07.09.2015

4 - Wheel description RO/ECE 1677-01 07.09.2015

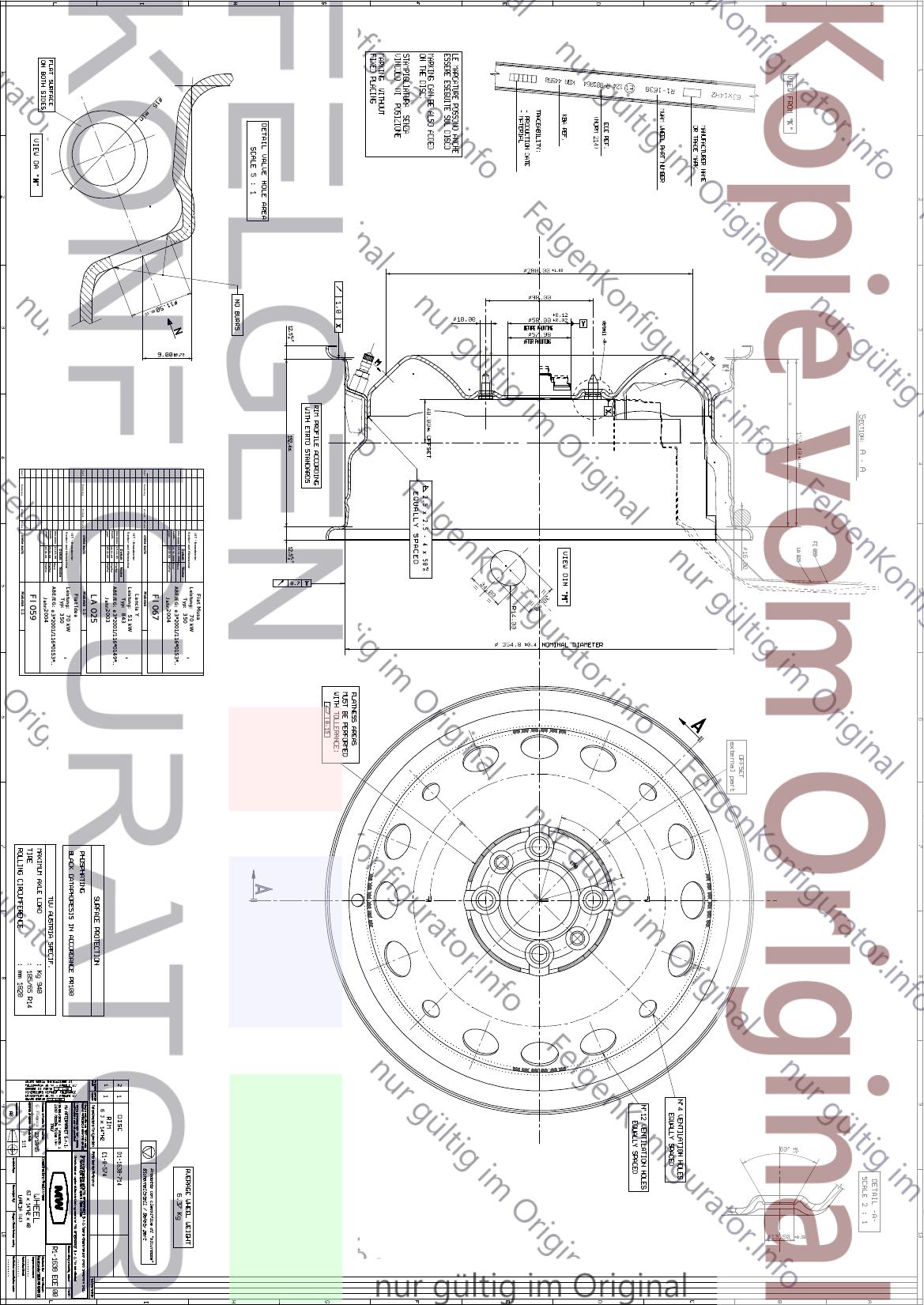

5 - Wheel drawing R1-1638 ECE 23.10.2015

6 - Materials testing RO/ECE 1860-01 07.09.2015

7 - Test report 366-0006-16-WIRD-TB 14.01.2016

8 - Assembly instructions (E1) 124R 001064 07.09.2015

9 - Field of application 1 application 14.01.2016

TÜV AUSTRIA AUTOMOTIVE GMBH RÄDER- UND REIFENPRÜFUNG DEUTSCHSTRAßE 10 1230 WIEN

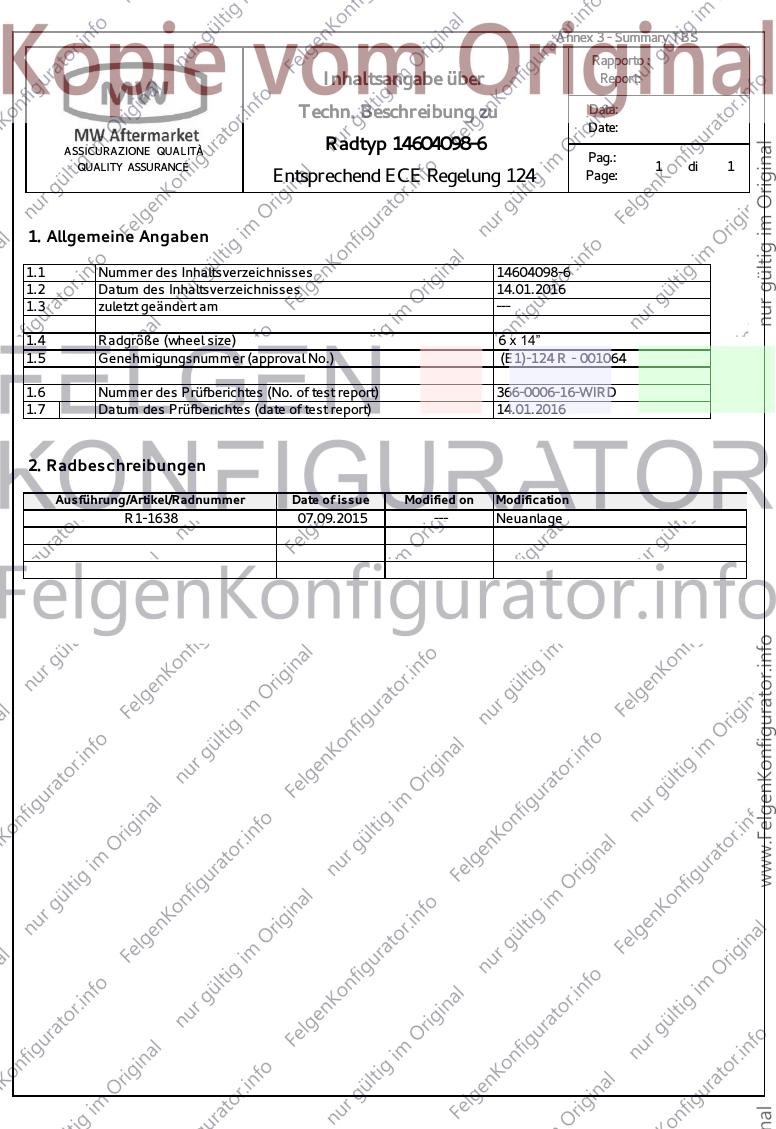

Annex 3 - Summary TBS

Rapporto :

Inhaltsangabe über Report:

Techn. Beschreibung zu Data:

Date:

ASSICURAZIONE QUALITÀ Radtyp 14604098-6

Pag.:

QUALITY ASSURANCE 1 di 1

Entsprechend ECE Regelung 124 Page:

1. Allgemeine Angaben

1.1 Nummer des Inhaltsverzeichnisses 14604098-6

1.2 Datum des Inhaltsverzeichnisses 14.01.2016

1.3 zuletzt geändert am ---

1.4 Radgröße (wheel size) 6 x 14”

1.5 Genehmigungsnummer (approval No.) (E1)-124 R - 001064

1.6 Nummer des Prüfberichtes (No. of test report) 366-0006-16-WIRD

1.7 Datum des Prüfberichtes (date of test report) 14.01.2016

2. Radbeschreibungen

Ausführung/Artikel/Radnummer Date of issue Modified on Modification

R1-1638 07.09.2015 --- Neuanlage

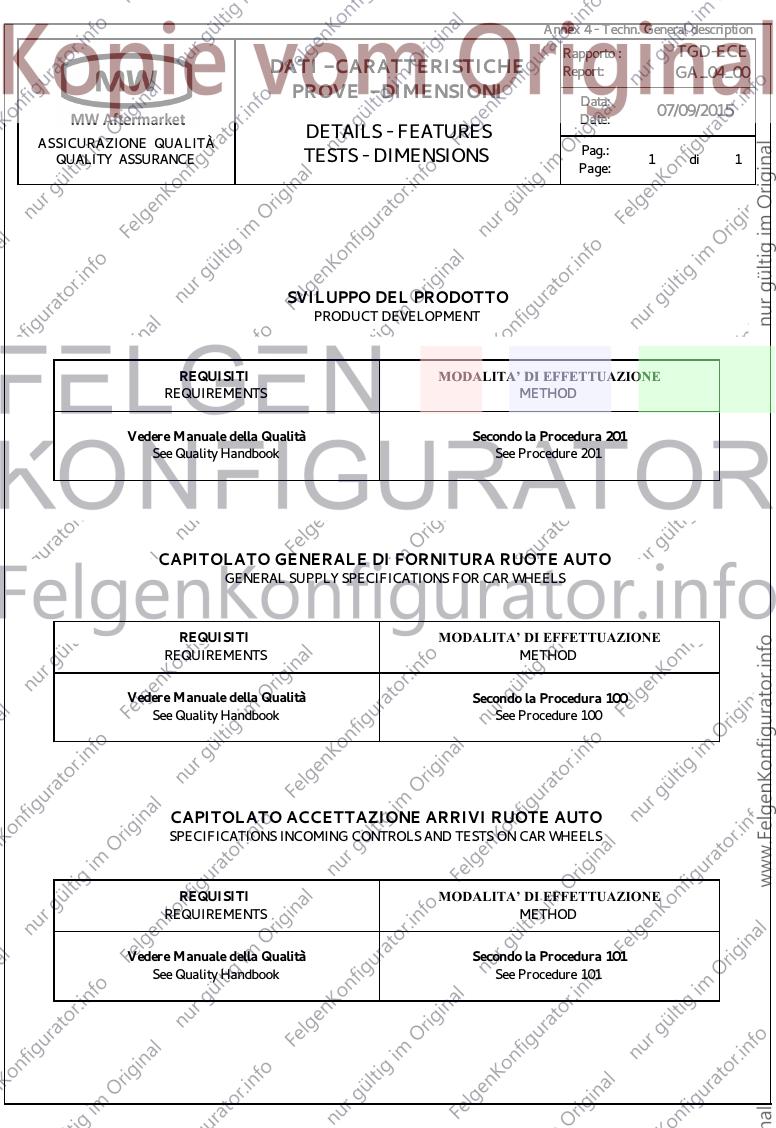

Annex 4 - Techn. General description

Rapporto : TGD-ECE

DATI - CARATTERISTICHE Report: GA_04_00

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 1 di 1

Page:

SVILUPPO DEL PRODOTTO

PRODUCT DEVELOPMENT

REQUISITI MODALITA’ DI EFFETTUAZIONE

REQUIREMENTS METHOD

Vedere Manuale della Qualità Secondo la Procedura 201

See Quality Handbook See Procedure 201

CAPITOLATO GENERALE DI FORNITURA RUOTE AUTO

GENERAL SUPPLY SPECIFICATIONS FOR CAR WHEELS

REQUISITI MODALITA’ DI EFFETTUAZIONE

REQUIREMENTS METHOD

Vedere Manuale della Qualità Secondo la Procedura 100

See Quality Handbook See Procedure 100

CAPITOLATO ACCETTAZIONE ARRIVI RUOTE AUTO

SPECIFICATIONS INCOMING CONTROLS AND TESTS ON CAR WHEELS

REQUISITI MODALITA’ DI EFFETTUAZIONE

REQUIREMENTS METHOD

Vedere Manuale della Qualità Secondo la Procedura 101

See Quality Handbook See Procedure 101

Annex 4 - Wheel description

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

07/09/2015

Date:

ASSICURAZIONE QUALITÀ

DETAILS - FEATURES

Pag.:

QUALITY ASSURANCE 1 di 4

TESTS - DIMENSIONS Page:

RUOTA SOSTITUTIVA REPLICA

REPLICA REPLACEMENT WHEEL

RUOTA:

WHEEL:

14"

TIPO :

TYPE : 14604098-6

R1-1638

Annex 4 - Wheel description

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

ASSICURAZIONE QUALITÀ DETAILS - FEATURES

Pag.:

QUALITY ASSURANCE TESTS - DIMENSIONS Page: 2 di 4

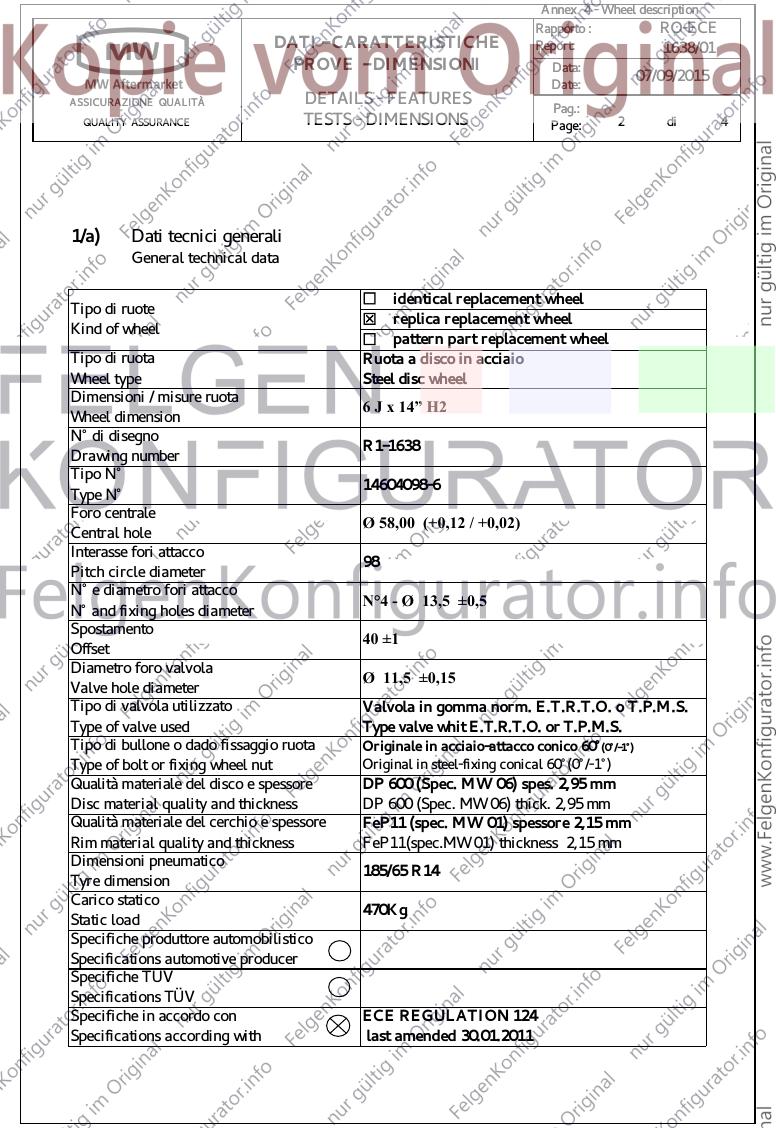

1/a) Dati tecnici generali

General technical data

identical replacement wheel

Tipo di ruote

Sreplica replacement wheel

Kind of wheel

pattern part replacement wheel

Tipo di ruota Ruota a disco in acciaio

Wheel type Steel disc wheel

Dimensioni / misure ruota

6 J x 14” H2

Wheel dimension

N° di disegno

R1-1638

Drawing number

Tipo N°

14604098-6

Type N°

Foro centrale

Ø 58,00 (+0,12 / +0,02)

Central hole

Interasse fori attacco

98

Pitch circle diameter

N° e diametro fori attacco

N°4 - Ø 13,5 ±0,5

N° and fixing holes diameter

Spostamento

40 ±1

Offset

Diametro foro valvola

Ø 11,5 ±0,15

Valve hole diameter

Tipo di valvola utilizzato Valvola in gomma norm. E.T.R.T.O. o T.P.M.S.

Type of valve used Type valve whit E.T.R.T.O. or T.P.M.S.

Tipo di bullone o dado fissaggio ruota Originale in acciaio-attacco conico 60°(0°/-1°)

Type of bolt or fixing wheel nut Original in steel-fixing conical 60°(0°/-1°)

Qualità materiale del disco e spessore DP 600 (Spec. MW 06) spes. 2,95 mm

Disc material quality and thickness DP 600 (Spec. MW 06) thick. 2,95 mm

Qualità materiale del cerchio e spessore FeP11 (spec. MW 01) spessore 2,15 mm

Rim material quality and thickness FeP11(spec.MW 01) thickness 2,15 mm

Dimensioni pneumatico

185/65 R14

Tyre dimension

Carico statico

470Kg

Static load

Specifiche produttore automobilistico

Specifications automotive producer

Specifiche TÜV

Specifications TÜV

Specifiche in accordo con ECE REGULATION 124

Specifications according with last amended 30.01.2011

Annex 4 - Wheel description

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 3 di 4

Page:

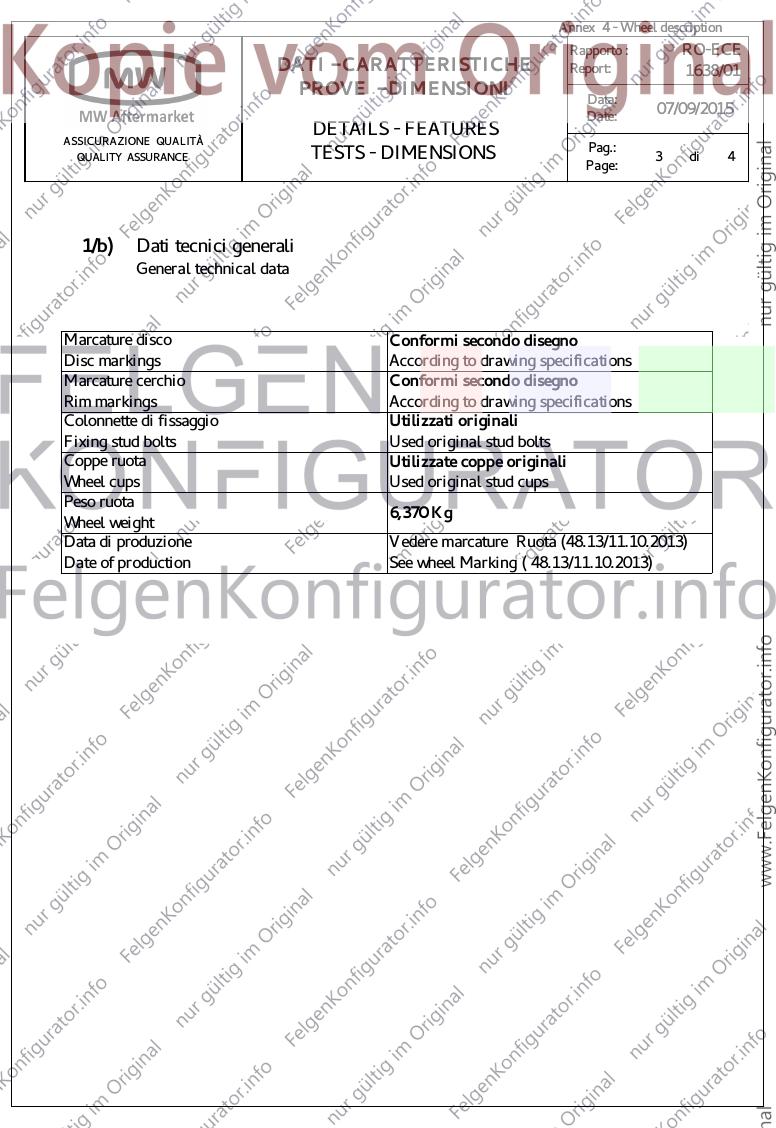

1/b) Dati tecnici generali

General technical data

Marcature disco Conformi secondo disegno

Disc markings According to drawing specifications

Marcature cerchio Conformi secondo disegno

Rim markings According to drawing specifications

Colonnette di fissaggio Utilizzati originali

Fixing stud bolts Used original stud bolts

Coppe ruota Utilizzate coppe originali

Wheel cups Used original stud cups

Peso ruota

6,370 Kg

Wheel weight

Data di produzione Vedere marcature Ruota (48.13/11.10.2013)

Date of production See wheel Marking ( 48.13/11.10.2013)

Annex 4 - Wheel description

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

07/09/2015

Date:

ASSICURAZIONE QUALITÀ

DETAILS - FEATURES

Pag.:

QUALITY ASSURANCE TESTS - DIMENSIONS Page: 4 di 4

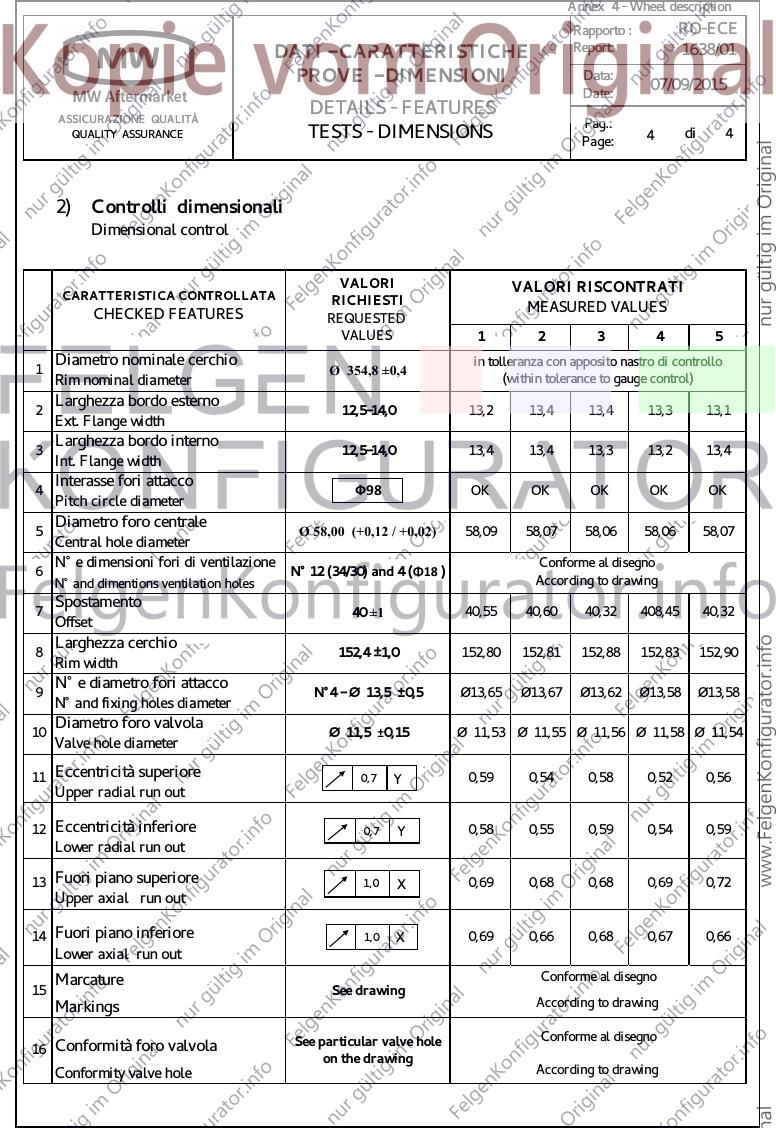

2) Controlli dimensionali

Dimensional control

VALORI VALORI RISCONTRATI

CARATTERISTICA CONTROLLATA RICHIESTI

CHECKED FEATURES MEASURED VALUES

REQUESTED

VALUES 1 2 3 4 5

Diametro nominale cerchio in tolleranza con apposito nastro di controllo

1 Ø 354,8 ±0,4

Rim nominal diameter (within tolerance to gauge control)

Larghezza bordo esterno

2 12,5-14,0 13,2 13,4 13,4 13,3 13,1

Ext. Flange width

Larghezza bordo interno

3 12,5-14,0 13,4 13,4 13,3 13,2 13,4

Int. Flange width

Interasse fori attacco

4 Ф98 OK OK OK OK OK

Pitch circle diameter

Diametro foro centrale

5 Ø 58,00 (+0,12 / +0,02) 58,09 58,07 58,06 58,06 58,07

Central hole diameter

N° e dimensioni fori di ventilazione Conforme al disegno

6 N° 12 (34/30) and 4 (Φ18 )

N° and dimentions ventilation holes According to drawing

Spostamento

7 40 ±1 40,55 40,60 40,32 408,45 40,32

Offset

Larghezza cerchio

8 152,4 ±1,0 152,80 152,81 152,88 152,83 152,90

Rim width

N° e diametro fori attacco

9 N°4 - Ø 13,5 ±0,5 Ø13,65 Ø13,67 Ø13,62 Ø13,58 Ø13,58

N° and fixing holes diameter

Diametro foro valvola

10 Ø 11,5 ±0,15 Ø 11,53 Ø 11,55 Ø 11,56 Ø 11,58 Ø 11,54

Valve hole diameter

11 Eccentricità superiore 0,7 Y 0,59 0,54 0,58 0,52 0,56

Upper radial run out

12 Eccentricità inferiore 0,7 Y 0,58 0,55 0,59 0,54 0,59

Lower radial run out

13 Fuori piano superiore 1,0 X 0,69 0,68 0,68 0,69 0,72

Upper axial run out

14 Fuori piano inferiore 1,0 X 0,69 0,66 0,68 0,67 0,66

Lower axial run out

Marcature Conforme al disegno

15 See drawing

Markings According to drawing

See particular valve hole Conforme al disegno

16 Conformità foro valvola

on the drawing

Conformity valve hole According to drawing

I S T - B re m sko n t u r

Fiat Musa

V o rd e r- u n d Hi n t e ra ch se L eistung: 7 0 kW

D atum N ame T yp: 3 50

A bn ah m e 1 8 . 11. 2004 M ar x

b earb.

ABE/ EG: e3* 2001/116* 0153*. .

2 5. 11. 2004 B ee r

g epr. 2 6. 11. 04 P f e if f er

J ahr:2 004

FI 067

Z us t Ä nd er un g D a tu m N ame s iehe auch: M aß stab

I S T - B re m sko n t u r

Lancia Y

V o rd e r- u n d Hi n t e ra ch se L eistung: 5 1 kW

D atum N ame T yp: 8 43

A bn ah m e 1 9. 1 1. 03 P f ei f f e r

b earb.

ABE/ EG: e3* 2001/116* 0149*. .

2 4. 11 . 03 P f ei f f e r

g epr. 2 5. 11. 03 P f e if f er

J ahr:2 003

LA 025

Z us t Ä nd er un g D a tu m N ame s iehe auch: M aß stab 1 :1

Fiat Idea

I S T - B re m sko n t u r

V o rd e r- u n d Hi n t e ra ch se L eistung: 7 0 kW

D atum N ame T yp: 3 50

A bn ah m e 2 1. 0 1. 04 M ar x

b earb.

ABE/ EG: e3* 2001/116* 0153*. .

2 9. 01 . 04 P f ei f f e r

g epr. 3 0. 01. 04 P f e if f er

J ahr:2 004

G. Florescu

FI 059

Z us t Ä nd er un g D a tu m N ame s iehe auch: M aß stab 1 :1

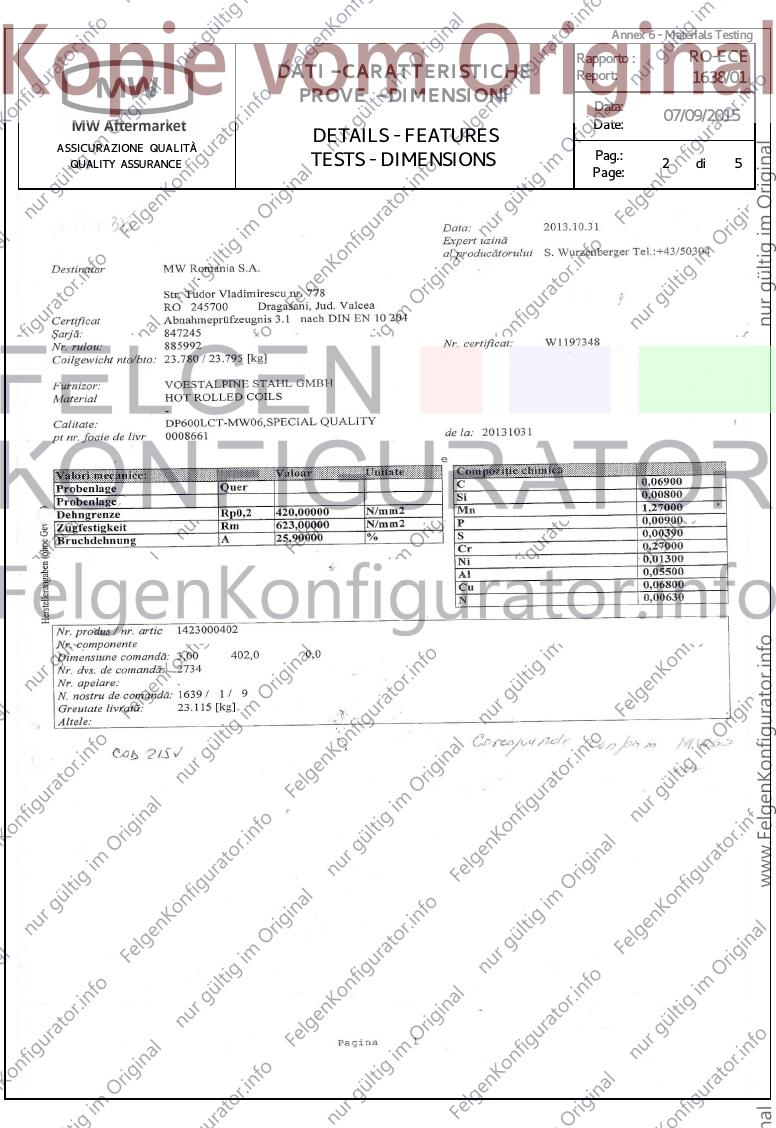

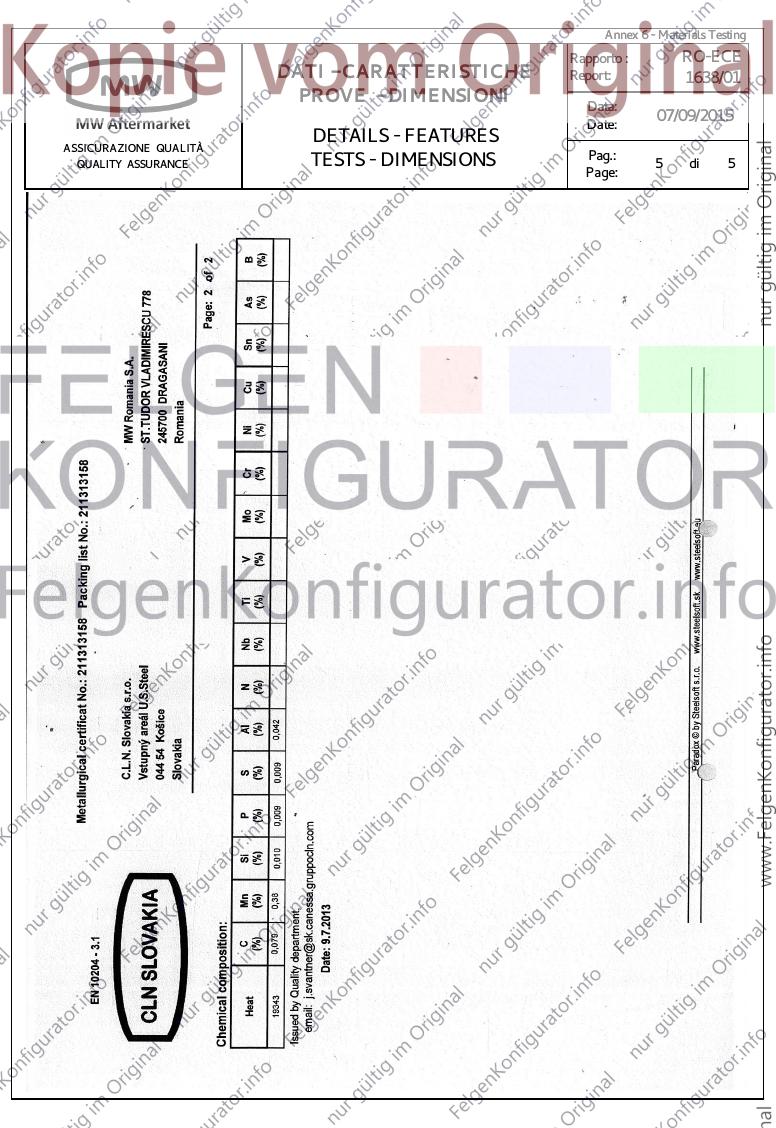

Annex 6 - Materials Testing

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 1 di 5

Page:

MATERIALE UTILIZZATO PER IL DISCO

MATERIAL USED FOR THE DISC

DP 600 (Spec. MW 06) spes. 2,95 mm

DP 600 (Spec. MW 06) thick. 2,95 mm

Annex 6 - Materials Testing

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 2 di 5

Page:

Allegare

Annex

Materiale disco: Certificato Qualità

Disc material: Quality Certificate

Annex 6 - Materials Testing

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 3 di 5

Page:

MATERIALE UTILIZZATO PER IL CERCHIO

MATERIAL USED FOR THE RIM

FeP11 (spec. MW 01) spessore 2,15 mm

FeP11(spec.MW 01) thickness 2,15 mm

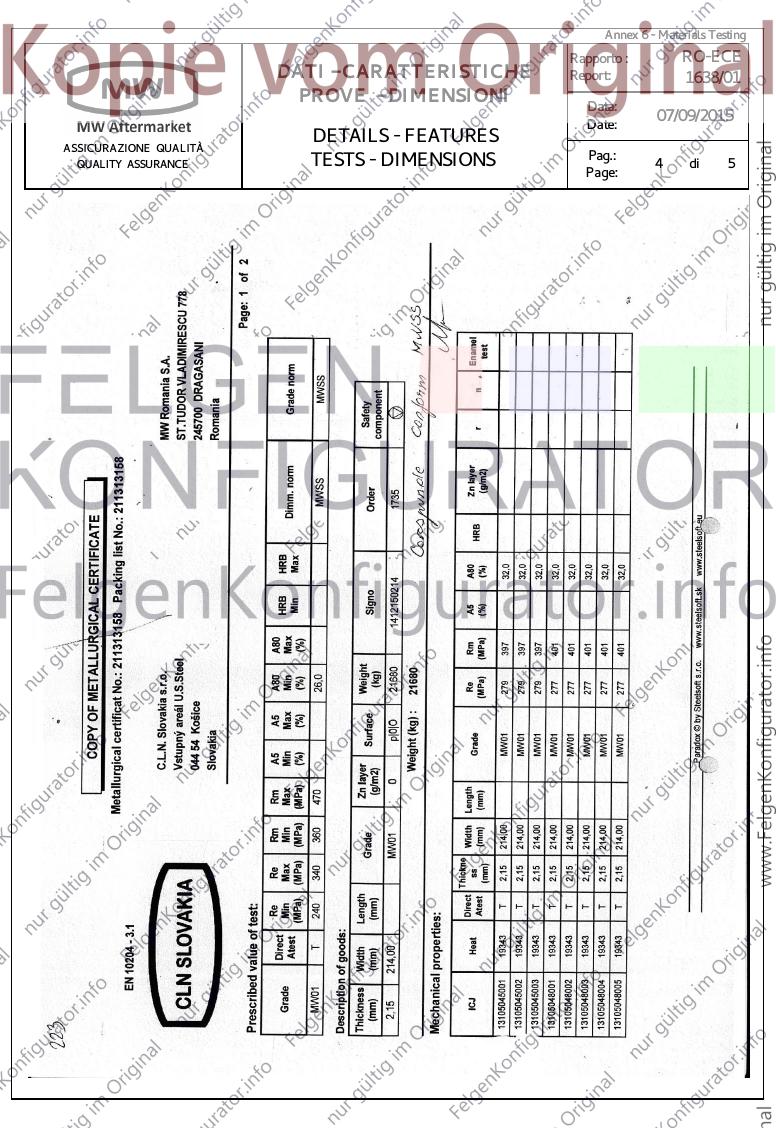

Annex 6 - Materials Testing

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 4 di 5

Page:

Allegare

Annex

Materiale cerchio: Certificato Qualità

Rim material: Quality Certificate

Annex 6 - Materials Testing

Rapporto : RO-ECE

DATI - CARATTERISTICHE Report: 1638/01

PROVE - DIMENSIONI Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 5 di 5

Page:

Allegare

Annex

Materiale cerchio: Certificato Qualità

Rim material: Quality Certificate

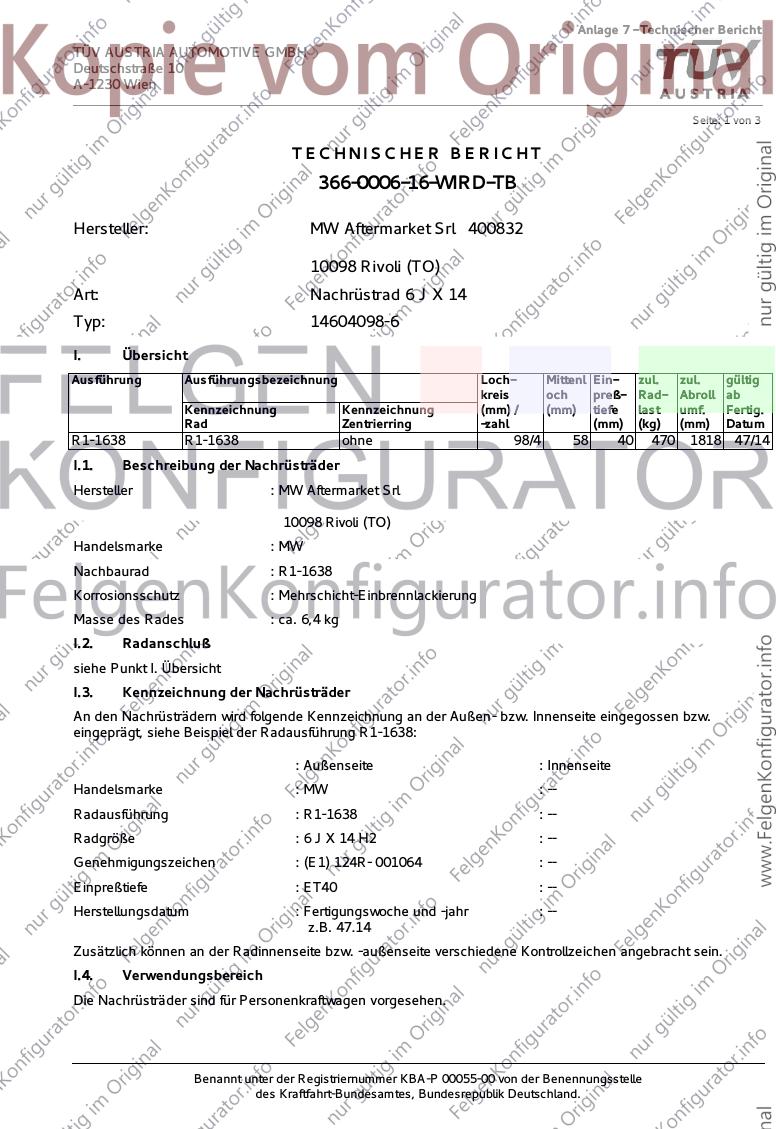

Anlage 7 - Technischer Bericht

TÜV AUSTRIA AUTOMOTIVE GMBH

Deutschstraße 10

A-1230 Wien

Seite: 1 von 3

T ECHNISCHER BERICHT

366-0006-16-WIRD-TB

Hersteller: MW Aftermarket Srl 400832

10098 Rivoli (TO)

Art: Nachrüstrad 6 J X 14

Typ: 14604098-6

I. Übersicht

Ausführung Ausführungsbezeichnung Loch- Mittenl Ein- zul. zul. gültig

kreis och preß- Rad- Abroll ab

Kennzeichnung Kennzeichnung (mm) / (mm) tiefe last umf. Fertig.

Rad Zentrierring -zahl (mm) (kg) (mm) Datum

R1-1638 R1-1638 ohne 98/4 58 40 470 1818 47/14

I.1. Beschreibung der Nachrüsträder

Hersteller : MW Aftermarket Srl

10098 Rivoli (TO)

Handelsmarke : MW

Nachbaurad : R1-1638

Korrosionsschutz : Mehrschicht-Einbrennlackierung

Masse des Rades : ca. 6,4 kg

I.2. Radanschluß

siehe Punkt I. Übersicht

I.3. Kennzeichnung der Nachrüsträder

An den Nachrüsträdern wird folgende Kennzeichnung an der Außen- bzw. Innenseite eingegossen bzw.

eingeprägt, siehe Beispiel der Radausführung R1-1638:

: Außenseite : Innenseite

Handelsmarke : MW : --

Radausführung : R1-1638 : --

Radgröße : 6 J X 14 H2 : --

Genehmigungszeichen : (E1) 124R- 001064 : --

Einpreßtiefe : ET40 : --

Herstellungsdatum : Fertigungswoche und -jahr : --

z.B. 47.14

Zusätzlich können an der Radinnenseite bzw. -außenseite verschiedene Kontrollzeichen angebracht sein.

I.4. Verwendungsbereich

Die Nachrüsträder sind für Personenkraftwagen vorgesehen.

Benannt unter der Registriernummer KBA-P 00055-00 von der Benennungsstelle

des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

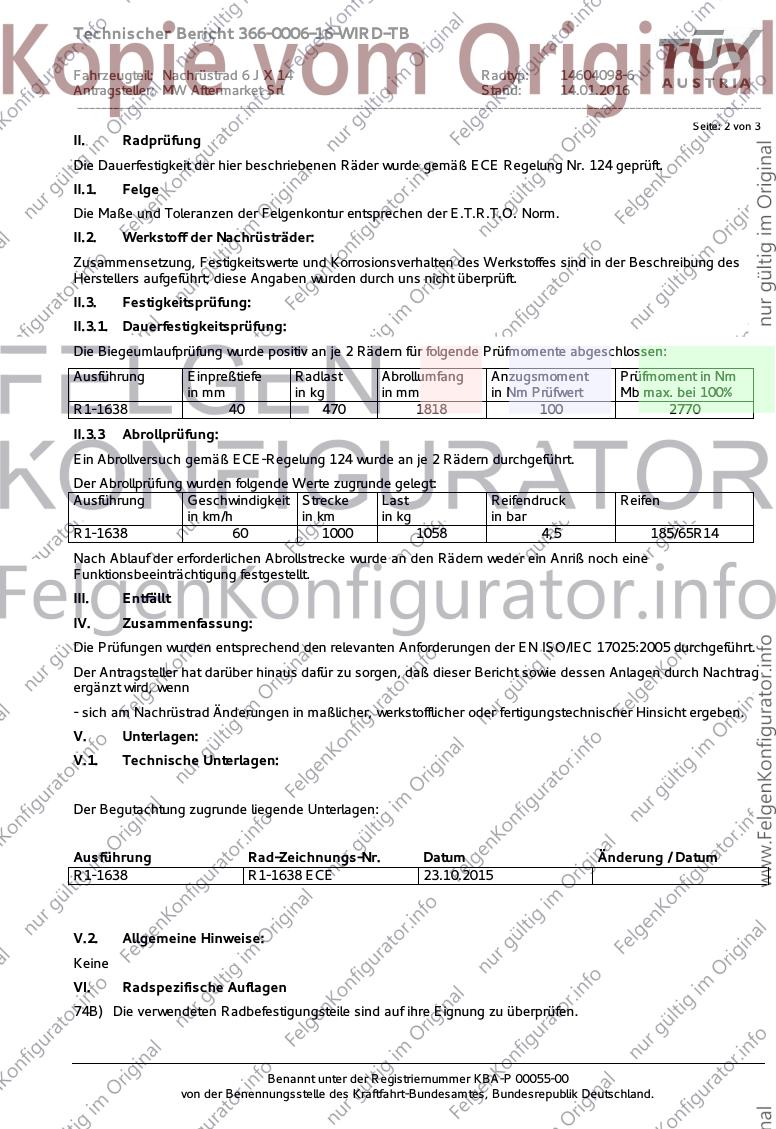

Technischer Bericht 366-0006-16-WIRD-TB

Fahrzeugteil: Nachrüstrad 6 J X 14 Radtyp: 14604098-6

Antragsteller: MW Aftermarket Srl Stand: 14.01.2016

__________________________________________________________________________________________________________________

Seite: 2 von 3

II. Radprüfung

Die Dauerfestigkeit der hier beschriebenen Räder wurde gemäß ECE Regelung Nr. 124 geprüft.

II.1. Felge

Die Maße und Toleranzen der Felgenkontur entsprechen der E.T.R.T.O. Norm.

II.2. Werkstoff der Nachrüsträder:

Zusammensetzung, Festigkeitswerte und Korrosionsverhalten des Werkstoffes sind in der Beschreibung des

Herstellers aufgeführt; diese Angaben wurden durch uns nicht überprüft.

II.3. Festigkeitsprüfung:

II.3.1. Dauerfestigkeitsprüfung:

Die Biegeumlaufprüfung wurde positiv an je 2 Rädern für folgende Prüfmomente abgeschlossen:

Ausführung Einpreßtiefe Radlast Abrollumfang Anzugsmoment Prüfmoment in Nm

in mm in kg in mm in Nm Prüfwert Mb max. bei 100%

R1-1638 40 470 1818 100 2770

II.3.3 Abrollprüfung:

Ein Abrollversuch gemäß ECE-Regelung 124 wurde an je 2 Rädern durchgeführt.

Der Abrollprüfung wurden folgende Werte zugrunde gelegt:

Ausführung Geschwindigkeit Strecke Last Reifendruck Reifen

in km/h in km in kg in bar

R1-1638 60 1000 1058 4,5 185/65R14

Nach Ablauf der erforderlichen Abrollstrecke wurde an den Rädern weder ein Anriß noch eine

Funktionsbeeinträchtigung festgestellt.

III. Entfällt

IV. Zusammenfassung:

Die Prüfungen wurden entsprechend den relevanten Anforderungen der EN ISO/IEC 17025:2005 durchgeführt.

Der Antragsteller hat darüber hinaus dafür zu sorgen, daß dieser Bericht sowie dessen Anlagen durch Nachtrag

ergänzt wird, wenn

- sich am Nachrüstrad Änderungen in maßlicher, werkstofflicher oder fertigungstechnischer Hinsicht ergeben.

V. Unterlagen:

V.1. Technische Unterlagen:

Der Begutachtung zugrunde liegende Unterlagen:

Ausführung Rad-Zeichnungs-Nr. Datum Änderung / Datum

R1-1638 R1-1638 ECE 23.10.2015

V.2. Allgemeine Hinweise:

Keine

VI. Radspezifische Auflagen

74B) Die verwendeten Radbefestigungsteile sind auf ihre Eignung zu überprüfen.

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Technischer Bericht 366-0006-16-WIRD-TB

Fahrzeugteil: Nachrüstrad 6 J X 14 Radtyp: 14604098-6

Antragsteller: MW Aftermarket Srl Stand: 14.01.2016

__________________________________________________________________________________________________________________

Seite: 3 von 3

Cinibulk

Sachverständiger

Prüflabor DIN EN ISO/IEC 17025

Wien, 14.01.2016

AB

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.

Annex 8 - Assembly Instructions

Rapporto : ECE

DATI - CARATTERISTICHE Report: AI-00

PROVE - DIMENSIONI

Data:

Date:

07/09/2015

DETAILS - FEATURES

ASSICURAZIONE QUALITÀ

TESTS - DIMENSIONS Pag.:

QUALITY ASSURANCE 1 di 1

Page:

Installation instructions for steel wheels (E1) 124R 001064

1. Carefully check the steel wheel before installation to ensure it is not damaged

2. Only use tyres listed in Annex 4, or those mentioned on the vehicle's registration document

3. Be careful! Installation must be performed by qualified personnel

4. Position the wheel on the hub so that the center hole of the wheel corresponds to the centering of

the hub, and make sure the wheel disc has full contact with the hub flange.

a- Check that the bolts are compatible with the mounting holes of the homologated wheel

b- Check that the length of the bolts is conform for mounting

c- Hold the wheel with one hand and tighten the bolts starting from the lowest one

d- Tighten the bolts in a criss-cross sequence

e- For tightening only use a screwer with torque control or a torque wrench.

f- Turn the mounted wheel on the hub to make sure that there is no interference with the

brake calipers

5. The wheel must be mounted only on the types of vehicle listed in the Annex

6. Attention! The bolts must not be lubricated and must be retightened after 50 km of driving

7. The tire pressure must be the one specified by the vehicle's manufacturer

8. The use of snow chains is only permitted if foreseen by the vehicle's manufacturer

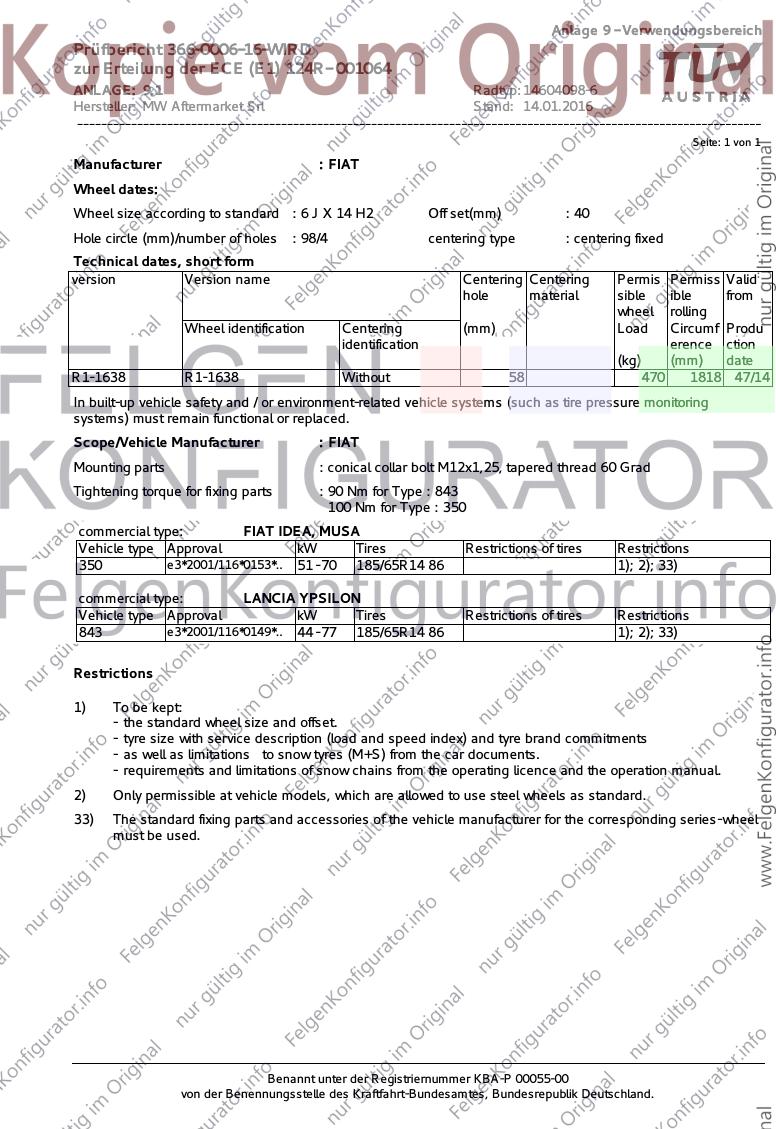

Anlage 9 - Verwendungsbereich

Prüfbericht 366-0006-16-WIRD

zur Erteilung der ECE (E1) 124R- 001064

ANLAGE: 9.1 Radtyp: 14604098-6

Hersteller: MW Aftermarket Srl Stand: 14.01.2016

__________________________________________________________________________________________________________________

Seite: 1 von 1

Manufacturer : FIAT

Wheel dates:

Wheel size according to standard : 6 J X 14 H2 Off set(mm) : 40

Hole circle (mm)/number of holes : 98/4 centering type : centering fixed

Technical dates, short form

version Version name Centering Centering Permis Permiss Valid

hole material sible ible from

wheel rolling

Wheel identification Centering (mm) Load Circumf Produ

identification erence ction

(kg) (mm) date

R1-1638 R1-1638 Without 58 470 1818 47/14

In built-up vehicle safety and / or environment-related vehicle systems (such as tire pressure monitoring

systems) must remain functional or replaced.

Scope/Vehicle Manufacturer : FIAT

Mounting parts : conical collar bolt M12x1,25, tapered thread 60 Grad

Tightening torque for fixing parts : 90 Nm for Type : 843

100 Nm for Type : 350

commercial type: FIAT IDEA, MUSA

Vehicle type Approval kW Tires Restrictions of tires Restrictions

350 e3*2001/116*0153*.. 51 - 70 185/65R14 86 1); 2); 33)

commercial type: LANCIA YPSILON

Vehicle type Approval kW Tires Restrictions of tires Restrictions

843 e3*2001/116*0149*.. 44 - 77 185/65R14 86 1); 2); 33)

Restrictions

1) To be kept:

- the standard wheel size and offset.

- tyre size with service description (load and speed index) and tyre brand commitments

- as well as limitations to snow tyres (M+S) from the car documents.

- requirements and limitations of snow chains from the operating licence and the operation manual.

2) Only permissible at vehicle models, which are allowed to use steel wheels as standard.

33) The standard fixing parts and accessories of the vehicle manufacturer for the corresponding series-wheel

must be used.

Benannt unter der Registriernummer KBA-P 00055-00

von der Benennungsstelle des Kraftfahrt-Bundesamtes, Bundesrepublik Deutschland.