�

.UDIWIDKUW�%XQGHVDPW�

'(�������)OHQVEXUJ�

0,77(,/81*�

(�1 ausgestellt von:

����������������.UDIWIDKUW�%XQGHVDPW�

über die Erweiterung einer Genehmigung

für einen Radtyp nach der Regelung Nr. 124 einschließlich Änderung Nr. 00

Ergänzung 01

&20081,&$7,21�

issued by:

R124 E1*124R00/01*0601*03

.UDIWIDKUW�%XQGHVDPW�

concerning the extension of an approval

of a wheel type, pursuant to Regulation No. 124 including amendment No 00

supplement 01

Genehmigungsnummer:�(�

���5�����

����

���

Approval number:

1. Radhersteller:

Wheel manufacturer:�

6XSHULRU�,QGXVWULHV�/HLFKWPHWDOOUlGHU�*HUPDQ\�*PE+

'(�������%DG�'UNKHLP

�

2. Typbezeichnung des Rades:

Wheel type designation:

;�������

�

2.1 Kategorie der Nachrüsträder:

Category of replacement wheels:

'LPHQVLRQVJOHLFKH�1DFKUVWUlGHU�

3DWWHUQ�SDUW�UHSODFHPHQW�ZKHHOV�

�

2.2 Werkstoff:

Construction material:

$OXPLQLXPOHJLHUXQJ�

$OXPLQLXP�DOOR\

�

� .UDIWIDKUW�%XQGHVDPW�

'(�������)OHQVEXUJ�

2

Genehmigungsnummer:�(�

���5�����

����

���

Approval number:

2.3 Fertigungsverfahren:

Method of production:

*HJRVVHQH�5lGHU�

&DVWHG�ZKHHOV�

�

2.4 Kennung der Felgenkontur:

Rim contour designation:

��-�

2.5 Einpresstiefe des Rades:

Wheel inset/outset:

6LHKH�3XQNW�����GHV�3UIEHULFKWHV�

R124 E1*124R00/01*0601*03

6HH�SRLQW�����RI�WKH�WHVW�UHSRUW�

�

2.6 Radbefestigung:

Wheel attachment:

*HPl�$QJDEHQ�LP�9HUZHQGXQJVEHUHLFK�GHV�3UIEHULFKWHV��

$FFRUGLQJ�WR�WKH�LQGLFDWLRQV�JLYHQ�LQ�WKH�UDQJH�RI�DSSOLFDWLRQ�RI�WKH�WHVW�UHSRUW�

�

2.7 Maximale Radlast und Abrollumfang:

Maximum wheel load and respective theoretical rolling circumference:

6LHKH�3XQNW�����GHV�3UIEHULFKWHV�

6HH�SRLQW�����RI�WKH�WHVW�UHSRUW�

3. Name und Anschrift des Herstellers:

Manufacturer‘s name and address:

6XSHULRU�,QGXVWULHV�/HLFKWPHWDOOUlGHU�*HUPDQ\�*PE+�

'(�������%DG�'UNKHLP�

4. Gegebenenfalls Name und Anschrift des Vertreters des Herstellers:

If applicable, name and address of manufacturer‘s representative:

(QWIlOOW�

1RW�DSSOLFDEOH

5. Datum, an dem das Rad für die Genehmigungsprüfung vorgeführt wurde:

Date on which the wheel was submitted for approval tests:

6LHKH�3XQNW�������

6HH�LWHP������

6. Technischer Dienst, der die Prüfungen für die Genehmigung durchführt:

Technical Service responsible for carrying out the approval test:

7HFKQRORJLH]HQWUXP�7\SSUIVWHOOH�GHU�7h9�3IDO]�9HUNHKUVZHVHQ�*PE+�

'(�������/DPEVKHLP�

� .UDIWIDKUW�%XQGHVDPW�

'(�������)OHQVEXUJ�

3

Genehmigungsnummer:�(�

���5�����

����

���

Approval number:

7. Datum des Gutachtens des Technischen Dienstes:

Date of test report issued by the Technical Service:

�������������

8. Nummer des Gutachtens des Technischen Dienstes:

Number of report issued by that service:

���������������$XVIHUWLJXQJ����

9. Bemerkungen:

Remarks:

(V�JHOWHQ�GLH�LP�R�J��*XWDFKWHQ�QHEVW�$QODJHQ�IHVWJHKDOWHQHQ�$QJDEHQ��

7KH�LQGLFDWLRQV�JLYHQ�LQ�WKH�DERYH�PHQWLRQHG�WHVW�UHSRUW�LQFOXGLQJ�LWV�

R124 E1*124R00/01*0601*03

DQQH[HV�VKDOO�DSSO\��

10. Die Genehmigung wird�HUZHLWHUW�

Approval is H[WHQGHG�

11. Grund (Gründe) für die Erweiterung der Genehmigung (falls zutreffend):

Reason(s) for the extension (if applicable):

$NWXDOLVLHUXQJ�GHV�9HUZHQGXQJVEHUHLFKHV�

8SGDWH�RI�UDQJH�RI�DSSOLFDWLRQ�

�

1DPH�XQG�RGHU�$QVFKULIW�GHV�*HQHKPLJXQJVLQKDEHUV�KDEHQ�VLFK�JHlQGHUW�

1DPH�DQG�RU�DGGUHVV�RI�WKH�DSSURYDO�KROGHU�KDV�EHHQ�FKDQJHG�

12. Ort: '(�������)OHQVEXUJ�

Place: �

�

13. Datum: �����������

Date:

14. Unterschrift: ,P�$XIWUDJ�

Signature: �

�

�

� 3UIEHULFKW�/ Test Report (&(�5�����������

�

$QODJH����annex 04�3UIEHULFKW���Test Report 1U���������������$XVIHUWLJXQJ����. version��

�

3UIJHJHQVWDQG���Test object� 3.:�1DFKUVWUDG���Pattern part replacement wheel��

� �-[��+��7\S���Type�;�������

�

+HUVWHOOHU���Manufacturer� 6XSHULRU�,QGXVWULHV�/HLFKWPHWDOOUlGHU�*HUPDQ\�*PE+�

�

6HLWH���YRQ���

�

3UIJHJHQVWDQG���Test object� � 'LPHQVLRQVJOHLFKHV�3.:�1DFKUVWUDG��

� � � � � Pattern part replacement wheel

�

$XV�� .HQQ]HLFKQXQJ�5DG���=HQWULHUULQJ /RFK]DKO��� (LQSUHVV�� 5DG�� $EUROOXPIDQJ�

IKUXQJ�� Marking wheel / ring� /RFKNUHLV�¡��PP��� WLHIH�� ODVW�� circumfer-

Version 0LWWHQORFK�¡��PP�� Inset Wheel ence���PP��

Number of holes/ �PP� load

pcd (mm)/ �NJ�

center hole-Ø (mm)

���:�� ;�������:����RKQH�5LQJ� ����������� ��� ���� �����

�

%HIHVWLJXQJVPLWWHO���Fixing elements�

�

1U�� $UW�GHU�%HIHVWLJXQJVPLWWHO�� %XQG� $Q]XJVPRPHQW�� 6FKDIWOlQJH��

Type of fixing parts Profile Torque �1P� Length �PP�

6��� 6HULHQVFKUDXEH�0��[����� .HJHO���� ���� ���

�

9HUZHQGXQJVEHUHLFK���Application

R124 E1*124R00/01*0601*03

+HUVWHOOHU�0DQXIDFWXUHU�� %0:�

�

+DQGHOVEH]HLFKQXQJ� N:�%HUHLFK 5HLIHQ� 5HLIHQEH]RJHQH�$XIODJHQ�XQG�+LQ� $XIODJHQ�XQG�

)DKU]HXJ�7\S� Power range� Tire size ZHLVH� +LQZHLVH��

$%(�(:*�1U�� Tire-referenced stipulations and Additional

Vehicle manufacturer/ notes� stipulations

model name/ type/ and notes�

approval number�

%0:��HU�5HLKH��9,,�� �������� ������5��� $���(&(�� $���$���$���

*�/� $���/���/LP�

H�

�������

����

��� 6���

%0:��HU�7RXULQJ��9,,�� �������� ������5��� $���$���(&(�� $���$���$���

*�.� &DU�)���/���

H�

�������

����

��� 6���

%0:��HU�5HLKH��9,�� �������� ������5��� $���(&(�� $���$���$���

�/� $���/���/LP�

H�

�������

����

������ 6���

��PLW�$OOUDGOHQNXQJ�

%0:��HU�5HLKH��9,�� �������� ������5��� $���(&(�� $���$���$���

�/� /���/LP�6���

H�

�������

����

������

��RKQH�$OOUDGOHQNXQJ�

%0:�0����L�G�['ULYH� ��������� ������5��� $���$���(&(�0�6�� $���$���$���

�9,,�� /���/LP�6���

*�/�

H�

�������

����

���

�

� �

7HFKQRORJLH]HQWUXP�7\SSUIVWHOOH�/DPEVKHLP���.|QLJVEHUJHU�6WUDH���G���'�������/DPEVKHLP�

� 3UIEHULFKW�/ Test Report (&(�5�����������

�

$QODJH����annex 04�3UIEHULFKW���Test Report 1U���������������$XVIHUWLJXQJ����. version��

�

3UIJHJHQVWDQG���Test object� 3.:�1DFKUVWUDG���Pattern part replacement wheel��

� �-[��+��7\S���Type�;�������

�

+HUVWHOOHU���Manufacturer� 6XSHULRU�,QGXVWULHV�/HLFKWPHWDOOUlGHU�*HUPDQ\�*PE+�

�

6HLWH���YRQ���

�

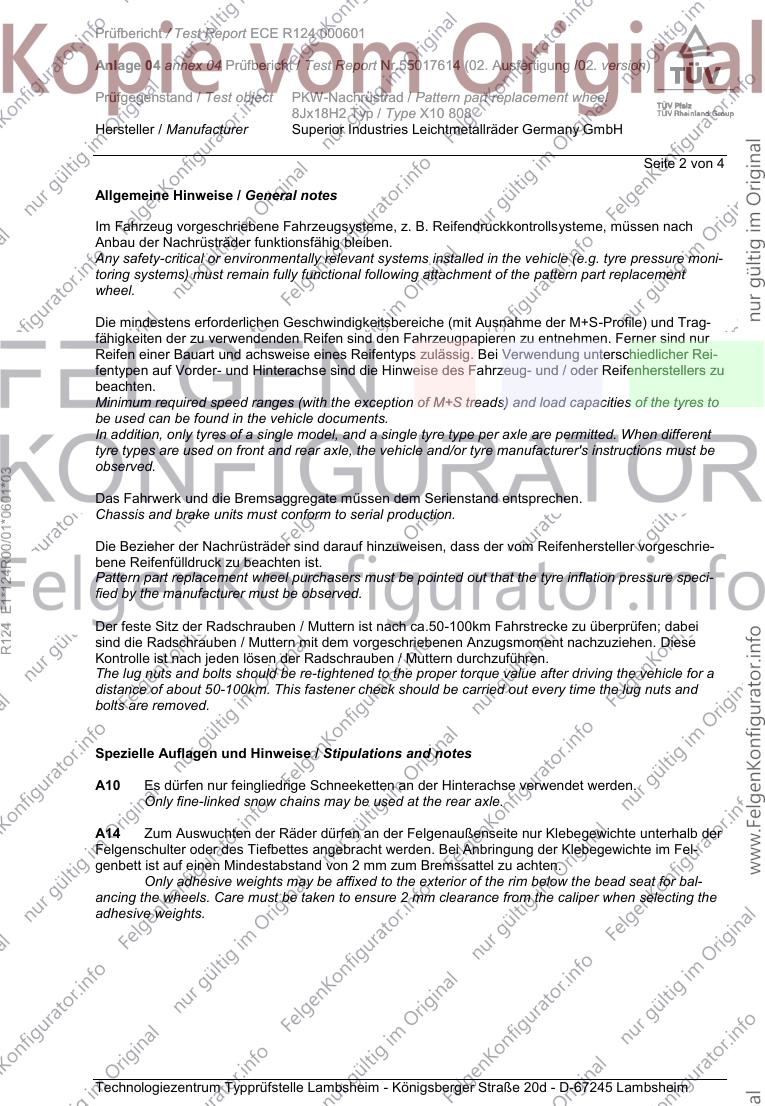

$OOJHPHLQH�+LQZHLVH���General notes�

�

,P�)DKU]HXJ�YRUJHVFKULHEHQH�)DKU]HXJV\VWHPH��]��%��5HLIHQGUXFNNRQWUROOV\VWHPH��PVVHQ�QDFK�

$QEDX�GHU�1DFKUVWUlGHU�IXQNWLRQVIlKLJ�EOHLEHQ��

Any safety-critical or environmentally relevant systems installed in the vehicle (e.g. tyre pressure moni-

toring systems) must remain fully functional following attachment of the pattern part replacement

wheel.

�

'LH�PLQGHVWHQV�HUIRUGHUOLFKHQ�*HVFKZLQGLJNHLWVEHUHLFKH��PLW�$XVQDKPH�GHU�0�6�3URILOH��XQG�7UDJ�

IlKLJNHLWHQ�GHU�]X�YHUZHQGHQGHQ�5HLIHQ�VLQG�GHQ�)DKU]HXJSDSLHUHQ�]X�HQWQHKPHQ��)HUQHU�VLQG�QXU�

5HLIHQ�HLQHU�%DXDUW�XQG�DFKVZHLVH�HLQHV�5HLIHQW\SV�]XOlVVLJ��%HL�9HUZHQGXQJ�XQWHUVFKLHGOLFKHU�5HL�

IHQW\SHQ�DXI�9RUGHU��XQG�+LQWHUDFKVH�VLQG�GLH�+LQZHLVH�GHV�)DKU]HXJ��XQG���RGHU�5HLIHQKHUVWHOOHUV�]X�

EHDFKWHQ��

Minimum required speed ranges (with the exception of M+S treads) and load capacities of the tyres to

be used can be found in the vehicle documents.

In addition, only tyres of a single model, and a single tyre type per axle are permitted. When different

tyre types are used on front and rear axle, the vehicle and/or tyre manufacturer's instructions must be

observed.

R124 E1*124R00/01*0601*03

�

'DV�)DKUZHUN�XQG�GLH�%UHPVDJJUHJDWH�PVVHQ�GHP�6HULHQVWDQG�HQWVSUHFKHQ��

Chassis and brake units must conform to serial production.

�

'LH�%H]LHKHU�GHU�1DFKUVWUlGHU�VLQG�GDUDXI�KLQ]XZHLVHQ��GDVV�GHU�YRP�5HLIHQKHUVWHOOHU�YRUJHVFKULH�

EHQH�5HLIHQIOOGUXFN�]X�EHDFKWHQ�LVW��

Pattern part replacement wheel purchasers must be pointed out that the tyre inflation pressure speci-

fied by the manufacturer must be observed.

'HU�IHVWH�6LW]�GHU�5DGVFKUDXEHQ���0XWWHUQ�LVW�QDFK�FD�������NP�)DKUVWUHFNH�]X�EHUSUIHQ��GDEHL�

VLQG�GLH�5DGVFKUDXEHQ���0XWWHUQ�PLW�GHP�YRUJHVFKULHEHQHQ�$Q]XJVPRPHQW�QDFK]X]LHKHQ��'LHVH�

.RQWUROOH�LVW�QDFK�MHGHQ�O|VHQ�GHU�5DGVFKUDXEHQ���0XWWHUQ�GXUFK]XIKUHQ��

The lug nuts and bolts should be re-tightened to the proper torque value after driving the vehicle for a

distance of about 50-100km. This fastener check should be carried out every time the lug nuts and

bolts are removed.

�

�

6SH]LHOOH�$XIODJHQ�XQG�+LQZHLVH���Stipulations and notes

�

$��� (V�GUIHQ�QXU�IHLQJOLHGULJH�6FKQHHNHWWHQ�DQ�GHU�+LQWHUDFKVH�YHUZHQGHW�ZHUGHQ��

� Only fine-linked snow chains may be used at the rear axle.�

�

$��� =XP�$XVZXFKWHQ�GHU�5lGHU�GUIHQ�DQ�GHU�)HOJHQDXHQVHLWH�QXU�.OHEHJHZLFKWH�XQWHUKDOE�GHU�

)HOJHQVFKXOWHU�RGHU�GHV�7LHIEHWWHV�DQJHEUDFKW�ZHUGHQ��%HL�$QEULQJXQJ�GHU�.OHEHJHZLFKWH�LP�)HO�

JHQEHWW�LVW�DXI�HLQHQ�0LQGHVWDEVWDQG�YRQ���PP�]XP�%UHPVVDWWHO�]X�DFKWHQ��

� Only adhesive weights may be affixed to the exterior of the rim below the bead seat for bal-

ancing the wheels. Care must be taken to ensure 2 mm clearance from the caliper when selecting the

adhesive weights.�

� �

7HFKQRORJLH]HQWUXP�7\SSUIVWHOOH�/DPEVKHLP���.|QLJVEHUJHU�6WUDH���G���'�������/DPEVKHLP�

� 3UIEHULFKW�/ Test Report (&(�5�����������

�

$QODJH����annex 04�3UIEHULFKW���Test Report 1U���������������$XVIHUWLJXQJ����. version��

�

3UIJHJHQVWDQG���Test object� 3.:�1DFKUVWUDG���Pattern part replacement wheel��

� �-[��+��7\S���Type�;�������

�

+HUVWHOOHU���Manufacturer� 6XSHULRU�,QGXVWULHV�/HLFKWPHWDOOUlGHU�*HUPDQ\�*PE+�

�

6HLWH���YRQ���

�

$��� (V�VLQG�QXU�VFKODXFKORVH�5HLIHQ�]XOlVVLJ��:HUGHQ�NHLQH�9HQWLOH�PLW�7306�6HQVRUHQ�YHUZHQ�

GHW��VLQG�0HWDOOVFKUDXEYHQWLOH�PLW�%HIHVWLJXQJ�YRQ�DXHQ�]XOlVVLJ��%HL�9HUZHQGXQJ�ELV�]X�HLQHU�

+|FKVWJHVFKZLQGLJNHLW�YRQ�����NP�K��EDXDUWEHGLQJWH�+|FKVWJHVFKZLQGLJNHLW��)]J��6FKHLQ��=LII����

E]Z��=XODVVXQJVEHVFKHLQLJXQJ�)HOG�7�RGHU�EHL�9HUZHQGXQJ�YRQ�:LQWHUUHLIHQ�PLW�*HVFKZLQGLJNHLWV�

V\PERO�4��5��6��7�RGHU�+��VLQG�DXFK�*XPPLYHQWLOH�]XOlVVLJ��:HUGHQ�9HQWLOH�PLW�7306�6HQVRUHQ�

YHUZHQGHW��VR�VLQG�GLH�+LQZHLVH�XQG�9RUJDEHQ�GHU�+HUVWHOOHU�]X�EHDFKWHQ��'LH�9HQWLOH�XQG�6HQVRUHQ�

PVVHQ�IU�GHQ�YRUJHVFKULHEHQHQ�/XIWGUXFN�XQG�GLH�+|FKVWJHVFKZLQGLJNHLW�JHHLJQHW�VHLQ��'LH�9HQWLOH�

PVVHQ�GHQ�1RUPHQ�(�7�5�7�2���',1�RGHU�7LUH�DQG�5LP�HQWVSUHFKHQ�XQG�GUIHQ�QLFKW�EHU�GHQ�)HO�

JHQUDQG�KLQDXVUDJHQ��

� Only tubeless tyres are permitted. If no TPMS sensors are used, metal screw valves with at-

tachment from outside are permitted. If the tyre is used up to a maximum speed of 210 km/h (maxi-

mum speed due to design as per former German vehicle license, item 6, or Certificate of Registration,

field T, or in the case of winter tyres with speed symbols Q, R, S, T or H), rubber valves are also ad-

missible. If valves with TPMS sensors are used, manufacturer recommendations and instructions must

be observed. Valves and sensors must be suited to the specified air pressure and maximum speed.

Valves must conform to E.T.R.T.O., DIN or Tire and Rim standards, and must not project beyond the

edge of the rim.�

�

R124 E1*124R00/01*0601*03

$��� 'LH�5DG�5HLIHQ�.RPELQDWLRQ�LVW�QXU�]XOlVVLJ�DQ�)DKU]HXJDXVIKUXQJHQ�PLW�$OOUDGDQWULHE��]�%��

�:'��4XDWWUR��6\QFUR����0DWLF���[��X��l���

� The wheel/tyre combination is only permissible on vehicle models with all-wheel drive (e.g.

4WD, Quattro, Syncro, 4-Matic, 4x4 and similar).�

�

$��� 'LHVH�5DG�5HLIHQ�.RPELQDWLRQ�HQ��LVW��VLQG��]XOlVVLJ�DQ�)DKU]HXJDXVIKUXQJHQ�PLW�)URQW�

E]Z��+HFN�$QWULHE�XQG�$OOUDGDQWULHE��]�%���:'���:'��4XDWWUR��6\QFUR����0DWLF���[���X��l���

� This (These) wheel/tyre combination(s) is (are) permitted on vehicle types with front wheel or

rear-wheel drive as well as 4-wheel drive (such as 2WD, 4WD, Quattro, Syncro, 4-Matic, 4x4 and simi-

lar types).�

�

$��� 'LH�9RUJDEHQ�XQG�+LQZHLVH�GHV�)DKU]HXJKHUVWHOOHUV�EH]JOLFK�GHU�9HUZHQGXQJ�YRQ�:LQWHU�

UHLIHQ��0�6�3URILO��XQG�6FKQHHNHWWHQ�VLQG�]X�EHDFKWHQ��V��%HWULHEVDQOHLWXQJ���

� Any recommendations given by the vehicle manufacturer relating to the use of snow tires and

snow chains must be observed (cf. User manual/instructions).�

�

&DU� 'LH�5DG�5HLIHQ�.RPELQDWLRQ�LVW�]XOlVVLJ�IU�)DKU]HXJDXVIKUXQJHQ�GHU�.DURVVHULHIRUP�.RP�

ELOLPRXVLQH��$YDQW��%UHDN��&DUDYDQ��.RPEL��6WDWLRQ�:DJRQ��7RXUHU��7XUQLHU��7RXULQJ������

� The wheel/tyre combination is permissible for vehicle models of the Avant, Caravan, estate-

car and/or touring variants.�

�

(&(� 'LH�9HUZHQGXQJ�GLHVHU�5DG�5HLIHQ�.RPELQDWLRQ�LVW�QXU�]XOlVVLJ��ZHQQ�VLH�EHUHLWV�VHULHQPl�

LJ�YRP�)DKU]HXJKHUVWHOOHU�IUHLJHJHEHQ�LVW��V��(*�hEHUHLQVWLPPXQJVEHVFKHLQLJXQJ���(WZDLJH�QRW�

ZHQGLJH�(LQVWHOOXQJHQ��+LQZHLVH�XQG�(PSIHKOXQJHQ�GHV�)DKU]HXJKHUVWHOOHUV�EHL�9HUZHQGXQJ�GLHVHU�

5DG�5HLIHQ�.RPELQDWLRQ�VLQG�]X�EHDFKWHQ��

� The use of this wheel/tyre combination is not permitted unless already previously approved by

the manufacturer for serial production (see EC Certificate of Conformity). Any necessary adjustments,

instructions and recommendations specified by the vehicle manufacturer in connection with the use of

this wheel/tyre combination must observed.�

�

)��� 5DG�5HLIHQNRPELQDWLRQ�QXU�]XOlVVLJ�DQ�)DKU]HXJDXVIKUXQJHQ�PLW�/XIWIHGHUXQJ�DQ�$FKVH����

� Wheel/tyre combination only permissible on vehicle models with air suspension at Axle 2.�

� �

7HFKQRORJLH]HQWUXP�7\SSUIVWHOOH�/DPEVKHLP���.|QLJVEHUJHU�6WUDH���G���'�������/DPEVKHLP�

� 3UIEHULFKW�/ Test Report (&(�5�����������

�

$QODJH����annex 04�3UIEHULFKW���Test Report 1U���������������$XVIHUWLJXQJ����. version��

�

3UIJHJHQVWDQG���Test object� 3.:�1DFKUVWUDG���Pattern part replacement wheel��

� �-[��+��7\S���Type�;�������

�

+HUVWHOOHU���Manufacturer� 6XSHULRU�,QGXVWULHV�/HLFKWPHWDOOUlGHU�*HUPDQ\�*PE+�

�

6HLWH���YRQ���

�

/��� 'LH�9HUZHQGXQJ�GLHVHU�5DG�5HLIHQ�.RPELQDWLRQ�HQ��LVW�VLQG��QXU�]XOlVVLJ�DQ�)DKU]HXJHQ�PLW�

$OOUDGOHQNXQJ���:6���

� The use of this wheel/tyre combination(s) is (are) only permissible on vehicles with all-wheel

steering.�

�

/��� 'LH�9HUZHQGXQJ�GLHVHU�5DG�5HLIHQ�.RPELQDWLRQ�HQ��LVW�VLQG��QLFKW�]XOlVVLJ�DQ�)DKU]HXJHQ�

PLW�$OOUDGOHQNXQJ���:6���

� The use of this wheel/tyre combination(s) is (are) not permissible on vehicles with all-wheel

steering.�

�

/��� 'LHVH�5DG�5HLIHQ�.RPELQDWLRQ�HQ��LVW��VLQG��]XOlVVLJ�DQ�)DKU]HXJDXVIKUXQJHQ�PLW�XQG�RKQH�

$OOUDGOHQNXQJ���:6���

� This wheel / tire combination (s) is (are) permitted on vehicle versions with and without four-

wheel steering (4WS).�

�

/LP� 'LH�5DG�5HLIHQ�.RPELQDWLRQ�LVW�]XOlVVLJ�IU�)DKU]HXJDXVIKUXQJHQ�GHU�.DURVVHULHIRUP�/L�

PRXVLQH��

� The wheel/tyre combination is permissible for vehicle models of the limousine variant.�

R124 E1*124R00/01*0601*03

�

0�6� 'LHVH�5HLIHQJU|H�LVW�QXU�]XOlVVLJ�DOV�0�6�%HUHLIXQJ��

� This tyre size is only permissible as mud and snow tyres.�

�

6��� =XU�%HIHVWLJXQJ�GHU�5lGHU�GUIHQ�QXU�GLH�VHULHQPlLJHQ�%HIHVWLJXQJVPLWWHO�1U��6����VLHKH�

6HLWH����YHUZHQGHW�ZHUGHQ��

� Only the serial fixing components No. S01 (see page 1) are to be used to attach the replace-

ment wheels.�

�

�

/DPEVKHLP�����0DL������

�

�

� � � � � � � � ���������'2&�

7HFKQRORJLH]HQWUXP�7\SSUIVWHOOH�/DPEVKHLP���.|QLJVEHUJHU�6WUDH���G���'�������/DPEVKHLP�

�Bad Dürkheim, 24.05.2019

3ÁHJHKLQZHLVH

für RIAL Leichtmetallfelgen

'DPLW�6LH�ODQJH�)UHXGH�DQ�,KUHQ�5,$/�/HLFKWPHWDOOIHOJHQ�KDEHQ��EHDFKWHQ�6LH�ELWWH�GLH�IROJHQGHQ�3ÁHJHKLQ-

ZHLVH��(LQÁVVH�ZLH�%UHPVVWDXE��6FKPXW]��)HXFKWLJNHLW��6DO]�XQG�6WHLQH�ODVVHQ�VLFK�QLFKW�YHUPHLGHQ��DEHU�LKUH�

$XVZLUNXQJ�DXI�GLH�)HOJHQ�OlVVW�VLFK�GXUFK�VRUJIlOWLJH�3ÁHJH�EHVHLWLJHQ�RGHU�PLQLPLHUHQ�

5(,1,*81*6,17(59$//(

Bleiben Verschmutzungen längere Zeit auf der Felge haften, kann dies zu Dauerschäden führen. Deshalb empfehlen wir Reinigungs-

intervalle von höchstens zwei Wochen. Dabei sollten die Räder außen und innen gründlich von allen Verschmutzungen befreit werden.

In der Winterzeit sollten die Felgen einmal pro Woche gereinigt werden. Kleine Lackschäden sind unbedingt sofort mit Klarlack auszu-

bessern, um eine unterwandernde Korrosion zu vermeiden.

5(,1,*81*60,77(/

Warmes Wasser mit Spülmittel oder Auto-Shampoo sind die Mittel der Wahl. Sollten Sie sich für Felgenreiniger entscheiden, beachten

Sie unbedingt die Herstellerangaben und die vorgegebene Einwirkzeit. Verzichten Sie auf säure-, laugen- oder alkoholhaltige Reini-

gungsmittel, da diese den Lack und eventuell auch das Bremssystem in Mitleidenschaft ziehen können.

5(,1,*81*67,336

• Um ein Eintrocknen des Reinigers zu vermeiden, sollten die Felgen bei der Reinigung kalt sein

• Verwenden Sie nur saubere und weiche Schwämme oder Bürsten

• Aggressive Reinigungsgegenstände und -mittel wie Stahlwolle oder Scheuersand sind bei einer Reinigung von Leichtmetallfelgen

fehl am Platz

• Falls Sie sich für einen Felgenreiniger entscheiden, überschreiten Sie auf keinen Fall dessen maximale Einwirkzeit

• Nach dem Reinigungsvorgang ist der Reiniger gründlich abzuwaschen

• Zu einer sorgfältigen Reinigung gehören immer auch die Innenseiten

• Bessern Sie Lackschäden sofort aus, um Oxidation zu verhindern

• Mit handelsüblicher Felgenversiegelung sorgen Sie im Übrigen für zusätzlichen Schutz, aber auch hier sind unbedingt die

Herstellerangaben zu beachten.

• Autowaschanlagen mit härteren Bürsten sollten Sie meiden

'LH�1LFKWEHDFKWXQJ�GLHVHU�3ÁHJHKLQZHLVH�IKUW�QLFKW�]XP�JHQHUHOOHQ�9HUOXVW�GHU�*DUDQWLHDQVSUFKH��NDQQ�

DEHU�]X�%HVFKlGLJXQJHQ�GHU�/HLFKWPHWDOOIHOJHQ�IKUHQ��GLH�QDFK�GHQ�YRUVWHKHQGHQ�*DUDQWLHEHGLQJXQJHQ�

QLFKW�XQWHU�GLH�*DUDQWLH�IDOOHQ�

*$5$17,($86)$//�%(,�'(5�62�*(1$117(1�Å237,6&+(1�5$'$8)%(5(,781*´�

Einige�Werkstätten bieten eine optische Rad- oder Felgenaufbereitung an und versprechen damit Schäden am Rad zu reparieren. Dieser

Vorgang ist ein schwerer Eingriff in die Beschaffenheit und Festigkeit einer Felge, z.B. durch spanende Verfahren oder starke Erhitzung,

und führt deshalb zum (UO|VFKHQ�GHU�*DUDQWLH! Aus Sicherheitsgründen raten wir dringend von der optischen Radaufbereitung ab.

Hersteller:

SUPERIOR INDUSTRIES Leichtmetallräder Germany GmbH

Gustav-Kirchhoff-Straße 10

67098 Bad Dürkheim

Germany

Tel.: +49 6322 9899 - 6000

ZZZ�ULDO�GH

Fax: +49 6322 9899 - 6001

E-Mail: kundenservice@supind.com

�Bad Dürkheim, Germany, May 24, 2019

&DUH�LQVWUXFWLRQV

for RIAL alloy wheels

7R�HQVXUH�\RXU�5,$/�DOOR\�ZKHHOV�EULQJ�\RX�ODVWLQJ�HQMR\PHQW��SOHDVH�REVHUYH�WKH�IROORZLQJ�LQVWUXFWLRQV��:KLOH�

EUDNH�GXVW��GLUW��PRLVWXUH��VDOW��VWRQHV�DQG�RWKHU�KD]DUGV�DUH�XQDYRLGDEOH��LW�LV�SRVVLEOH�WR�SUHYHQW�RU�DW�OHDVW�

PLQLPL]H�DQ\�GDPDJH�WKURXJK�DSSURSULDWH�ZKHHO�FDUH�

5(*8/$5�&/($1,1*

If dirt remains on the wheel for an extended period, this can lead to permanent damage. For this reason, we recommend regular clea-

ning, at intervals of no more than two weeks. Thoroughly clean both the outside and the inside of the wheel to remove all dirt. In winter,

WKH�ZKHHOV�VKRXOG�EH�FOHDQHG�RQFH�D�ZHHN��0LQRU�GDPDJH��FKLSSLQJ��WR�WKH�SDLQW�ÀQLVK�VKRXOG�EH�UHSDLUHG�XVLQJ�FOHDU�FRDW��YDUQLVK��WR�

SUHYHQW�FRUURVLRQ�RI�WKH�XQGHUO\LQJ��VXUURXQGLQJ�PDWHULDO��ÀOLIRUP�FRUURVLRQ���

&/($1,1*�$*(176

We recommend warm water with detergent (dish soap) or car shampoo. If you decide to use specialist wheel cleaner, please strictly ob-

serve the manufacturer’s instructions, especially regarding application time. Do not use cleaners that contain acids, alkalis or alcohols,

DV�WKHVH�FDQ�QHJDWLYHO\�LPSDFW�WKH�SDLQW�ÀQLVK�DQG�SRVVLEO\�HYHQ�WKH�FDU·V�EUDNLQJ�V\VWHP��

$'9,&(�21�&/($1,1*

• When being cleaned, the wheels should be cold to prevent the cleaner from drying out

• Use clean and soft sponges and brushes only

• Do not use aggressive cleaning agents or materials, such as steel wool or scouring sand

• If you decide to use a specialist wheel cleaner, do not under any circumstances exceed the maximum recommended

exposure/application time

• Once cleaning is complete, rinse off the cleaner thoroughly

• Thorough cleaning should always include the inner-facing surfaces of the wheel

� 5HSDLU�GDPDJH�WR�WKH�SDLQW�ÀQLVK�LPPHGLDWHO\�WR�SUHYHQW�R[LGDWLRQ

• Standard wheel sealant can be employed for added protection, but again be sure to comply with the manufacturer’s instructions

• Please avoid using car washes that feature rigid or hard brushes

)DLOXUH�WR�IROORZ�WKHVH�LQVWUXFWLRQV�GRHV�QRW�JHQHUDOO\�QXOOLI\�WKH�SURGXFW�ZDUUDQW\�LQ�LWV�HQWLUHW\��EXW�FDQ�OHDG�

WR�GDPDJH�WR�WKH�DOOR\�ZKHHOV�WKDW��LQ�DFFRUGDQFH�ZLWK�WKH�DSSOLFDEOH�WHUPV�DQG�FRQGLWLRQV��DUH�QRW�FRYHUHG�E\�

WKH�ZDUUDQW\��

,19$/,'$7,21�2)�:$55$17<�,1�7+(�(9(17�2)�5()85%,6+0(17

Some repair shops offer alloy wheel refurbishment, restoration or similar services, and promise to repair damage to the wheel. These

services have a serious impact on the wheel’s attributes and strength, for example entailing machining or heat treatment. As a result, the

use of these or similar services�LQYDOLGDWHV�WKH�SURGXFW�ZDUUDQW\. For safety reasons, we strongly advise against the use of such

services.

Manufacturer:

SUPERIOR INDUSTRIES Leichtmetallräder Germany GmbH

Gustav-Kirchhoff-Straße 10

67098 Bad Dürkheim

Germany

Tel.: +49 6322 9899 - 6000

ZZZ�ULDO�GH

Fax: +49 6322 9899 - 6001

E-Mail: customerservice@supind.com

�